NeuralJet™: AI-Driven Precision Droplet Control

NeuralJet™ is Elephantech’s proprietary AI-based droplet landing control technology, developed specifically to optimize high-precision inkjet printing. It simultaneously compensates for and absorbs a wide range of error factors arising from the inkjet head and mechanical system, enabling highly precise ejection of micro metal-ink droplets.

NeuralJet™, inkjet printing can reproduce ultra-fine patterns with fidelity to the desired level, delivering consistent, accurate and reliable production quality.

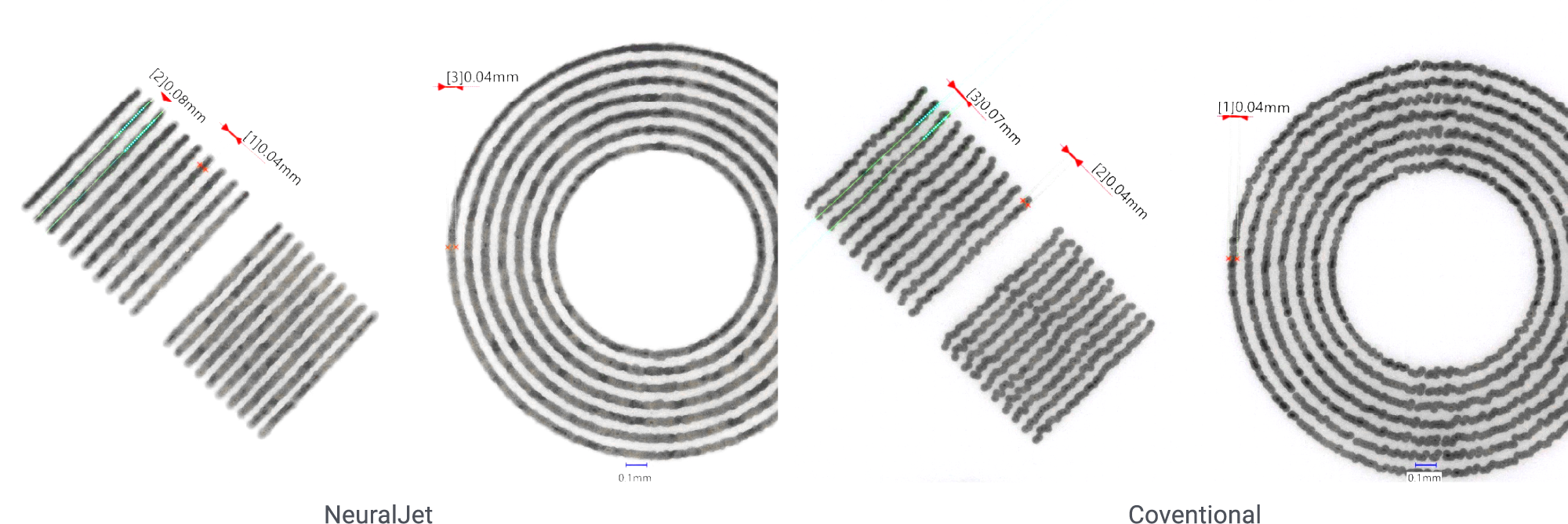

Comparison of printing results with and without NeuralJet™ on the same printer.

Highlight 1: Ultra-High Precision

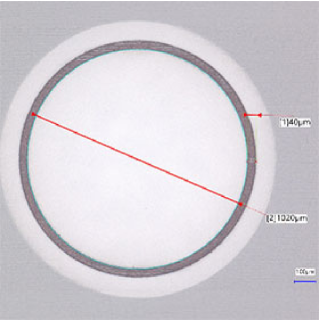

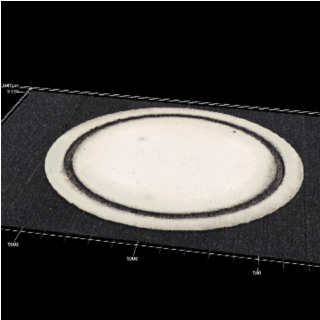

Even with general-purpose piezo chips, NeuralJet™ maintains tight droplet placement, keeping the average landing error to just 1.74 µm*1. In real-world precision tests ejecting 2,596 droplets of 4.8pL ink into 40 µm-wide grooves, it achieved 100% in-well landing with no outliers.

Filling φ40µm circular wells

3D imaging of φ40µm circular wells

FFilling 40µm wide circular grooves

F3D imaging of 40µm wide circular grooves

Highlight 2: Fluid Control and Mechine Control Co-Design

NeuralJet™ is not a case of “AI fixing everything afterward.” It is co-developed with inkjet printer’s fluid control, mechanical system to ensure effective and efficient control over hardware behaviors, delivering the greatest synergy.

Instead of minimizing every error through conventional control alone, the system is designed to minimize the types of errors that AI has difficulty interpreting—especially long-context or irregular ejection variations.

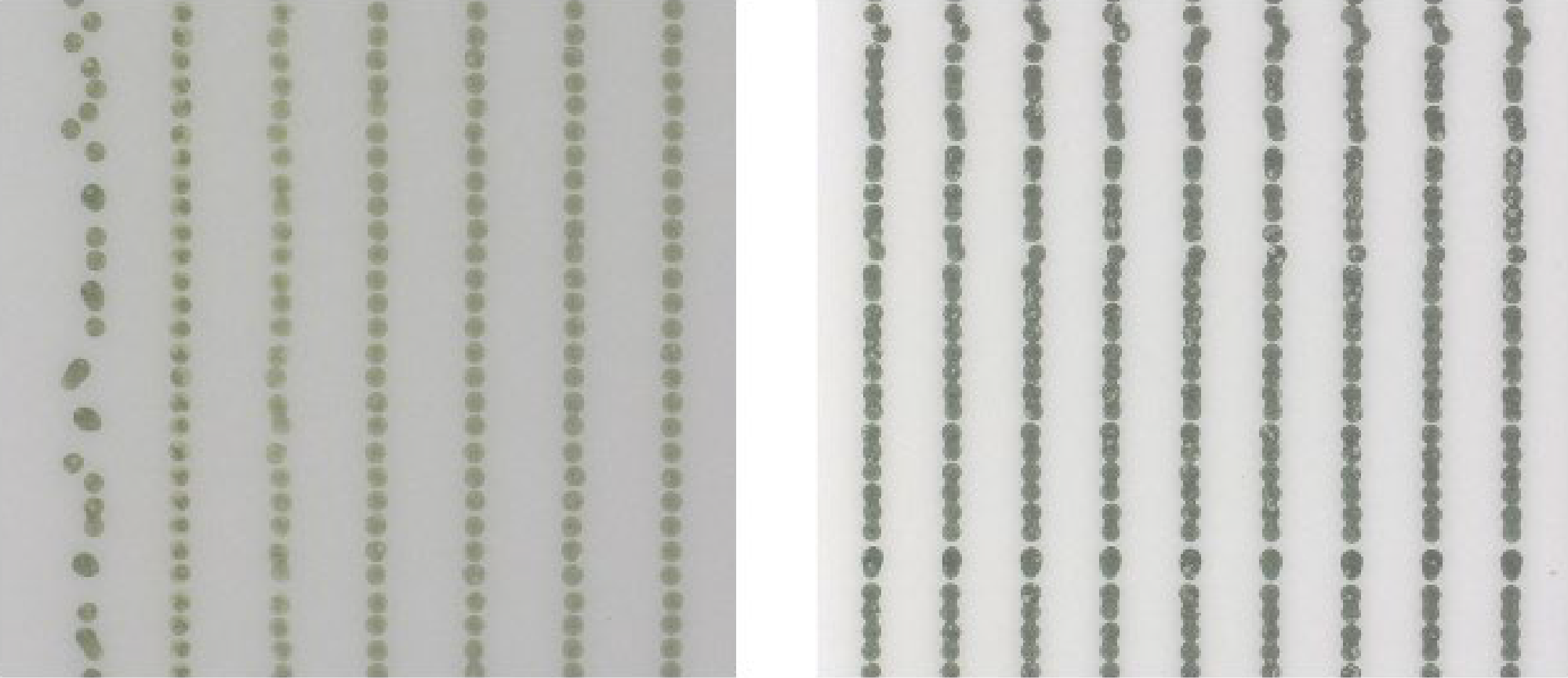

The photos below illustrate how different control conditions influence the ejection state: both patterns deviate from the ideal, but the right one is much easier for AI to model and correct, enabling significantly higher final accuracy.

Comparison of ejection deviation: non-reproducible vs. reproducible (easier for AI to adjust)

Highlight 3: AI on Local Compute

NeuralJet™ is designed to run on local GPU/CPU resources*2, enabling retraining offline whenever needed directly at the manufacturing site, without relying on cloud access or external computing infrastructure.

While it continues to learn and refine its accuracy from the datasets, NeuralJet™ is intentionallly engineered to remain lightweight enough to run stably on local hardware, allowing reliable and secure operations within production environments.

Highlight 4: Mass Production Expertise

Mass production environments require high process capability, consistent throughput, and minimal downtime. NeuralJet™ supports these needs by eliminating manual adjustment in critical steps such as printhead replacement, calibration and routine maintenance, ensuring consistency regardless of operator skill or behavior.

As production scales, number of nozzles also grows, and nozzle failure rates tend to rise accordingly.NeuralJet™ continuously optimizes the ejection path based on nozzle conditions, greatly improving the system’s tolerance to nozzle variability. Even when using worn printheads, NeuralJet maintains stable printing output by adapting to nozzle states.

*1: Average droplet-landing error of 1.74 µm for 643 droplets randomly placed within an 80× 80mm work area.

*2: Typical configuration operates on embedded controllers integrated with ELP04 printing systems, with GPU and other computing resources scaled appropriately to the equipment specification.