Advanced Specialty Materials: from Nanoparticles to High-Performance Devices

Elephantech’s technology begins with copper nanoparticle ink, the first material developed by the company and still is its fundamental asset. Through continuous R&D, Elephantech has established an integrated materials development framework encompassing nanofillers, conductive inks, primers and the advanced analytical technologies that support them. Together, they form the foundation of Elephantech’s proprietary additive electronics manufacturing process, enabling scalable, sustainable and high-precision production.

Groundbreaking Copper Nanofiller:Foundation of Conductive Materials

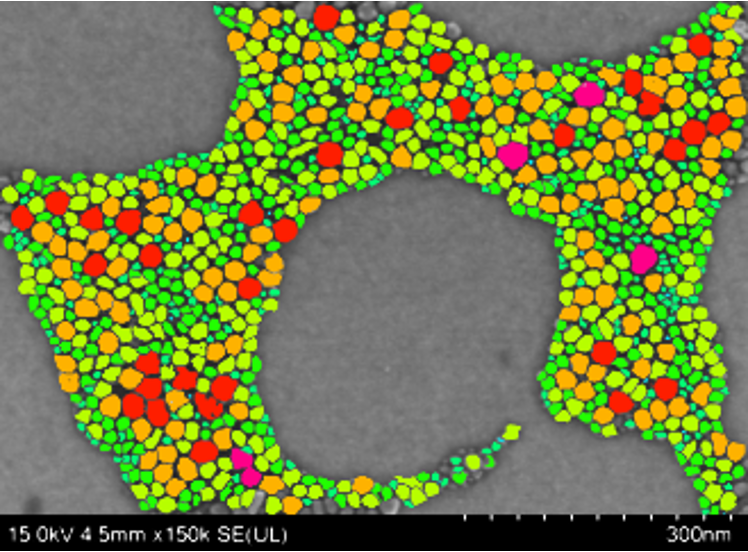

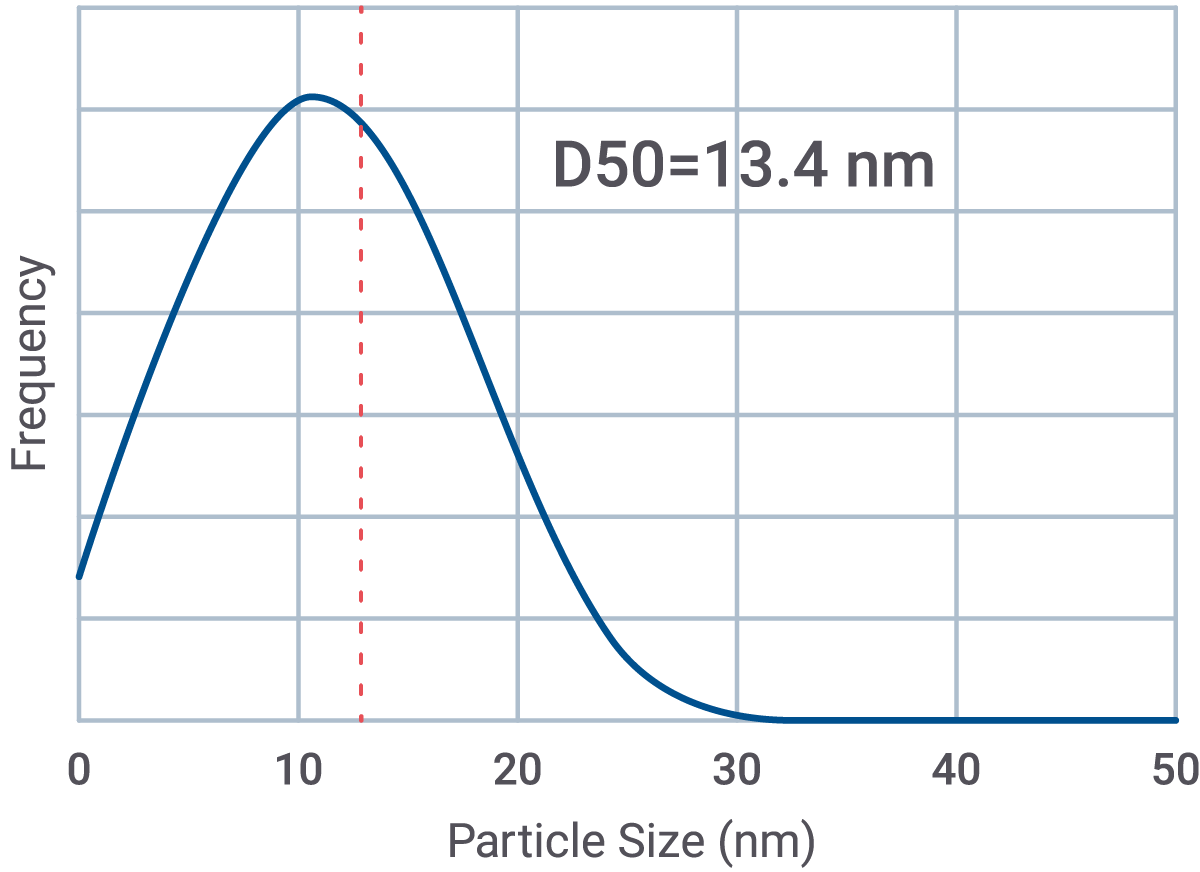

Elephantech’s copper nanofiller is made using the company’s fine-metal synthesis technology, delivers exceptional electrical and thermal conductivity. Our latest offering features ultra-fine particles averaging 15 nm, among the smallest of the kind worldwide.

These particles enable wet reduction at temperatures as low as 60 °C, greatly enhancing process stability and compatibility with various base materials. They also exhibit outstanding dispersion stability for up to six months, ensuring consistent quality over long periods and supporting high-volume manufacturing.

With these strengths, Elephantech’s copper nanofillers serve as a versatile material for inks, pastes, bonding agents, and heat-dissipating materials, contributing to innovation across multiple fields.

Copper nanofiller's SEM image

Copper nanofiller's particle size distribution

Copper Nanoink: Core for Additive Circuit Creation

As a direct application of the copper nanofiller, Elephantech’s copper nanoink marks a key constitute of its SustainaCircuits® process, the disruptive additive manufacturing method for conductive seed-layer formation via inkjet printing.

The characteristics of the ink impact every step of the production chain: from storage, printing, and sintering to final circuit trace. Its stability, particle size, solvent volatility, sinterability and adhesion to the substrate collectively determine conductivity, reliability and yield throughout the process.

Elephantech’s copper nanoink delivers industry-leading stability and processability, enabling both simplified manufacturing operations and consistently high-quality circuit traces.

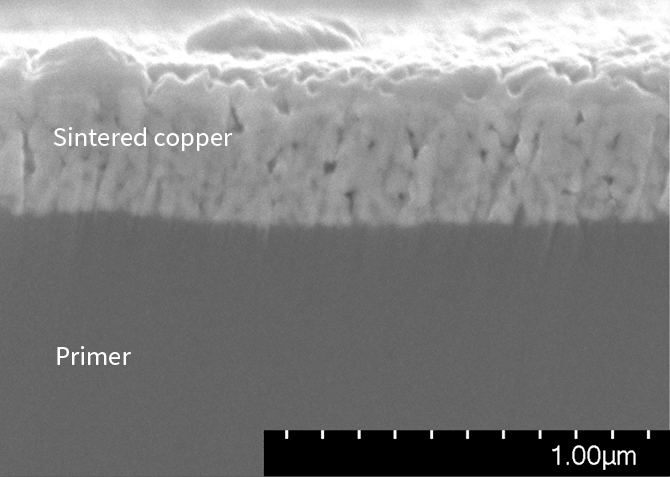

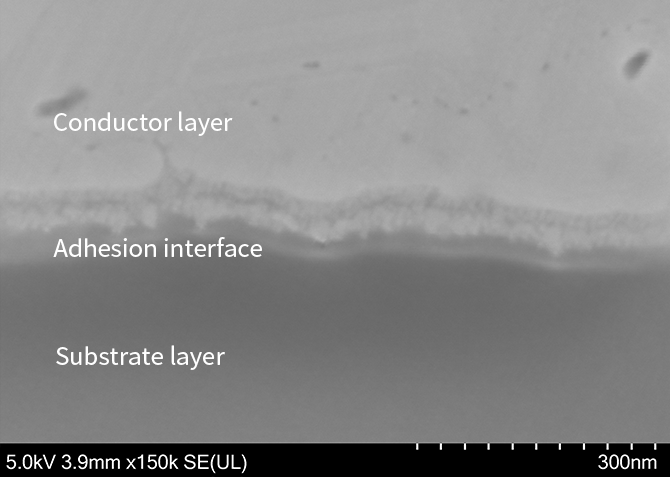

Cross-section SEM image of the ink-primer interface after sintering

Primer Technology: Dramatically Enhances Productivity

Complementing the nano ink, Elephantech’s uniquely formulated epoxy-based primer plays a crucial role in achieving reliable, fine-line circuitry through 3 mechanisms:

- Enhanced adhesion: The primer forms a strong physical bond between the ink and the base material, improving adhesion strength.

- Cross-material compatibility: With high affinity for the ink, the primer ensures smooth trace formation across diverse substrates from flexible films to rigid boards and glass.

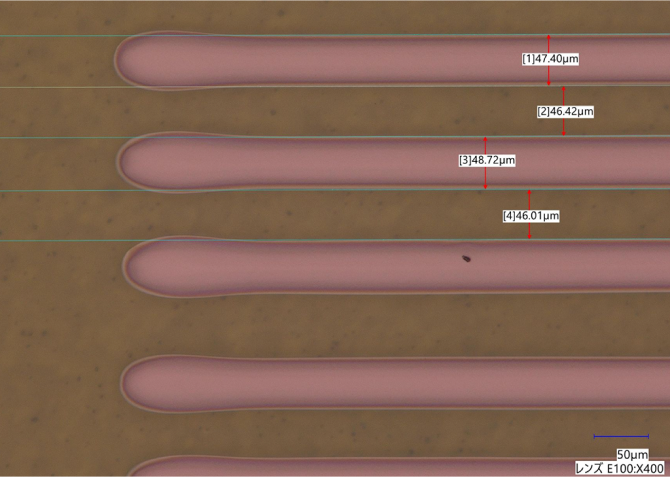

- Droplet control: During the inkjet printing process, the pre-coated primer stabilizes droplet landing behavior, enabling precise, fine wiring patterns.

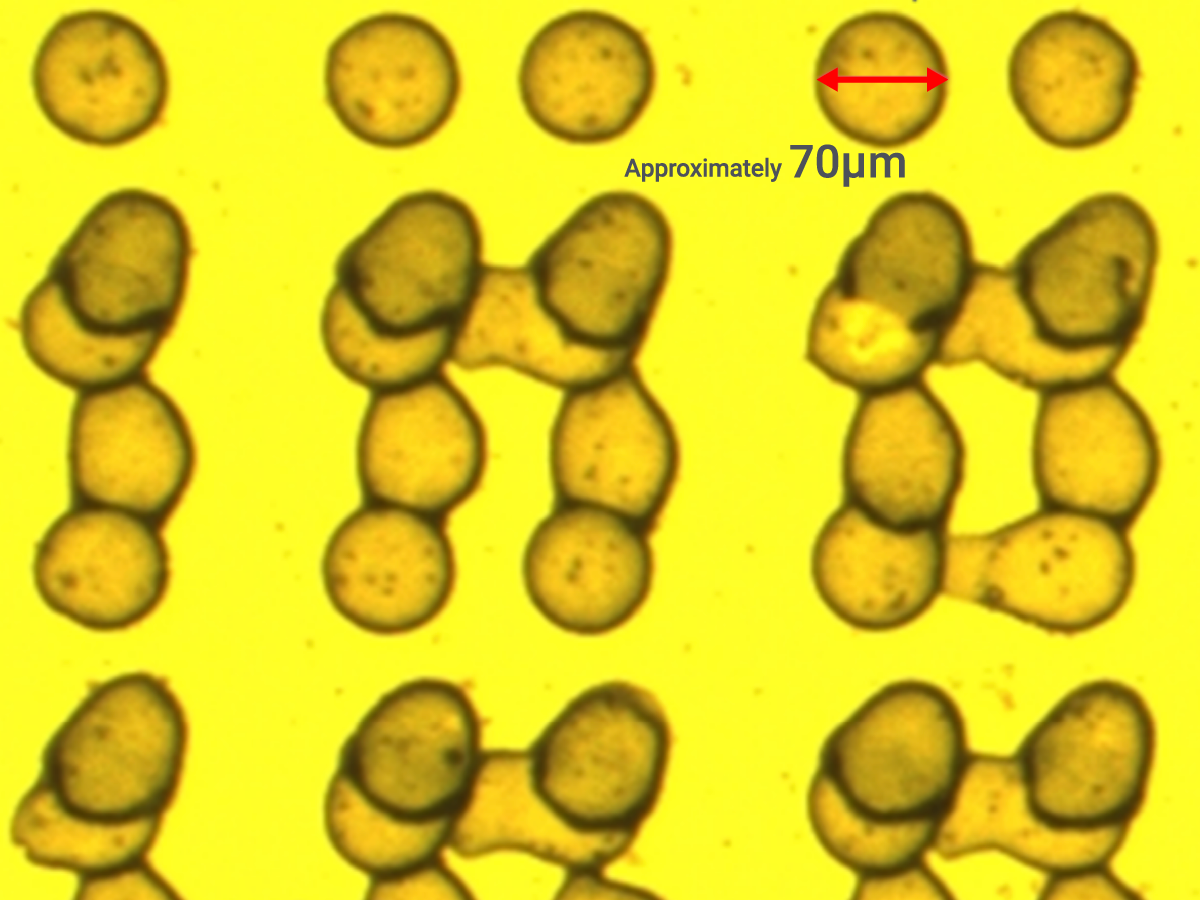

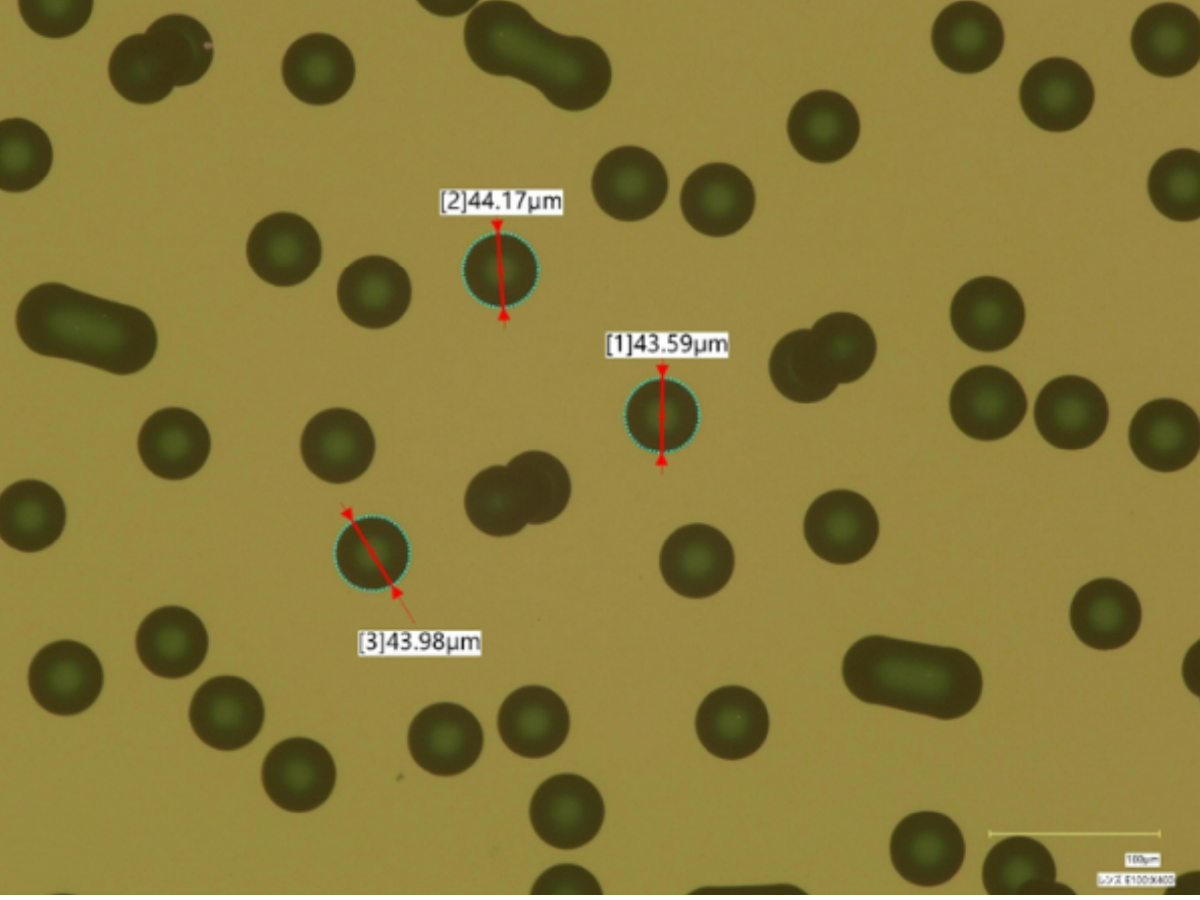

Minimized droplet landing diameter with controlled droplet behavior

Fine-pattern formation challenged by adjacent droplet merging and shape distortion

With primer applied, droplet merging and distortion are effectively suppressed, enabling fine-pattern formation

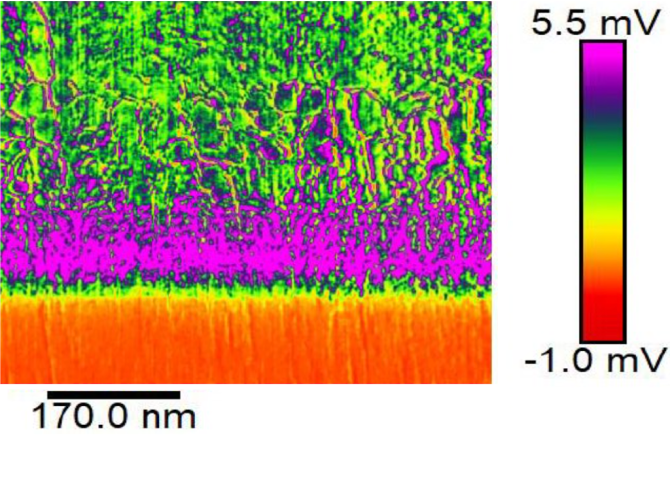

Material Analysis Technology That Ensures Quality Development

Advanced material innovation relies on deep analytical insight at the nano scale. From the early stage of research, Elephantech employs comprehensive analytical techniques to understand molecular behavior and root causes beneath the mysterious phenomenon of material science.

The findings serve as the foundation for the company to design particles with properties tailored for reliable electronics manufacturing.

Cross-sectional SEM image of the adhesion between the substrate and the conductor layer

AFM-IR measurement results: Specific molecular bonding spectra extracted and mapped to identify atomic states at the conductor-substrate interface