ELP04: Leading the Additive Future of Electronics Manufacturing

Inkjet printing, a technology enabling contactless, picoliter-scale deposition of functional inks only where needed, represents an ideal approach for additive manufacturing of conductive layers at the heart of printed electronics.

Yet large-scale adoption of inkjet printing has long been constrained by the difficulty of achieving high-precision and productivity at the same time.

Elephantech’s latest industrial inkjet printing platform, ELP04, manages to overcome these conventional barriers through the optimized integration of AI-driven accuracy, advanced mechanical configuration and optimized process. Engineered from the ground up for next-generation electronics, the ELP04 lineup sets a new benchmark for electronics manufacturing, delivering precision at 1μm-class level, output stability and scalability.

Highlight 1: Balancing Precision and Productivity

The ELP04 features a mechanically robust architecture that can maintain droplet placement accuracy even at high speeds, as well as a long printhead capable of supporting fast printing processes.

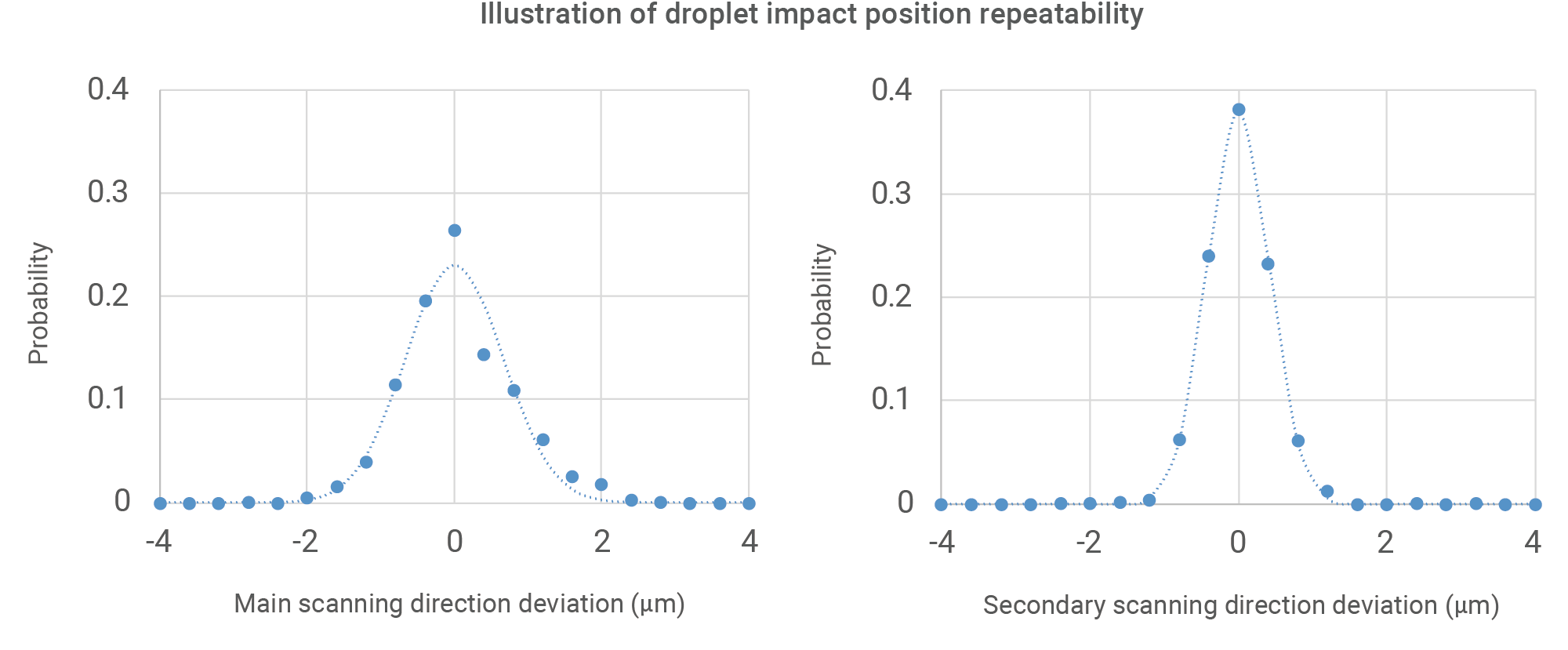

ELP04 delivers 1-µm-level*1 landing repeatability under high-speed operating conditions. Besides, it is equipped with NeuralJet™, Elephantech’s proprietary AI-based droplet landing-position correction system, which automatically compensates for positional deviations caused by mechanical axis distortion or individual nozzle characteristics.

The dual-effect enables the formation of ultra-fine conductive patterns essential for the next generation of miniaturized electronic components.

Our in-house FPC production model ELP0400 features an approximately 600-mm-wide printhead array, capable of printing an 830-mm-long panel in about 6.2 seconds per pass. In mass production, it is expected to achieve a productivity rate of 30 square meter per hour by completing a 500*830 mm sheet in around 31 seconds (five passes).

Highlight 2: Long-Term Stability for Mass Production

Leveraging the extensive know-how accumulated through mass-production operations, Elephantech has built the ELP04 series to incorporate a wide range of functions that ensure long-term performance. Through automatic maintenance functions such as ink ejection routines and nozzle surface wiping, the system ensures high ejection reliability through an ink-circulation mechanism that routes ink all the way to the vicinity of the nozzles.

In addition, it is equipped with advanced control features designed to prevent interruptions in mass-production, such as a landing diameter correction through drive-voltage control for of each printhead, and nozzle-status inspection that detects the discharge condition of all nozzles and feeds the results back to the print data. Through these capabilities, the ELP04 delivers stability and maintainability in the long run, enabling seamless integration into existing production lines and consistently providing high-quality output.

Highlight 3: Vertically Integrated Nanomaterials and Mechanical Control

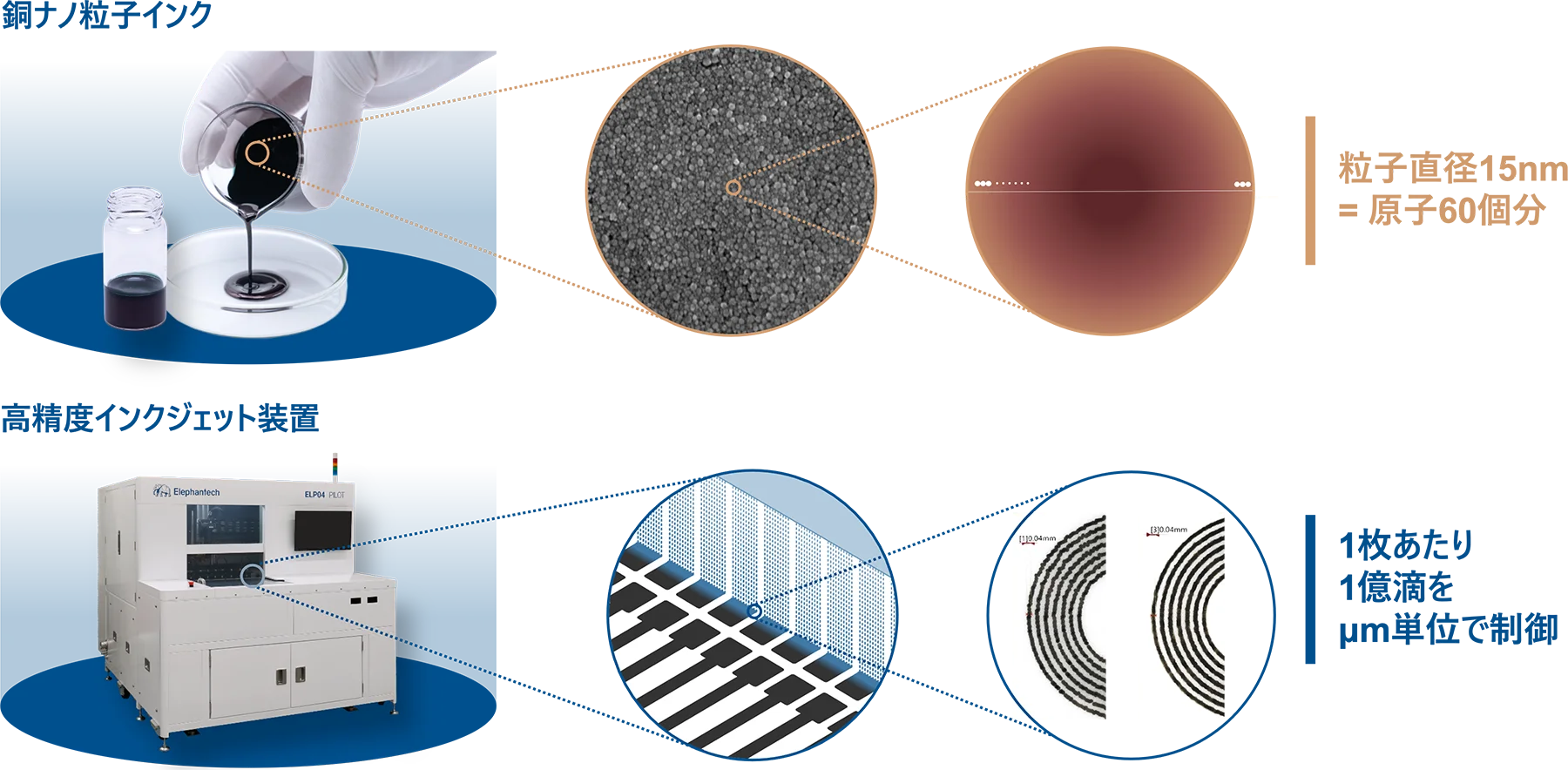

The ELP04’s greatest power lies in Elephantech’s unique integration of fluid dynamics, mechanical precision and mathematical optimization algorithms to create a vertically developed technology stack. The solution spans nano-ink formulation that employs world-class 15 nm copper nanomaterials with a diameter of just 60 atoms, and precise positional control of 100 million ink droplets per panel.

By holistically combining these technological strengths, the integration achieves optimal inkjet performance and brings out the strongest synergy across materials, mechanics and control system.

Elephantech’s Vertical Technology Integration

Originally developed as Elepantech’s in-house production system for SustainaCircuits FPCs, the ELP04 platform has evolved into a versatile inkjet solution product lineup that supports a broad range of applications, from seed-layer formation to next-generation printed electronic components, addressing diverse and rapidly changing needs of global electronics manufacturers.

*1: The large-scale production equipment installed at our Nagoya factory achieves a repeatable impact position accuracy (σ) of 0.75 μm in the main scanning direction and 0.44 μm in the secondary scanning direction.