Elephantech Innovates Cost- and Eco-efficient SustainaCircuits™ FPC Lineup to Include Cu-foil Thickness Less Than 1 μm and Over 100 μm, Now in Mass Production

- Elephantech expands its proprietary printed circuit boards lineup, SustainaCircuits™ by introducing new flexible printed circuits (FPCs), now in mass production. The new FPCs feature copper foils with thicknesses under 1µm and over 100µm.

- By incorporating inkjet and plating technologies, Elephantech has achieved substantial environmental benefits (70-80% less copper usage) and cost savings–particularly notable with thick copper-foil FPCs.

- Thick copper-foil FPCs are engineered to meet the high-current transmission demands in power electronics arena such as automotive and industrial equipment. Several projects of introducing mass production for various applications are currently underway.

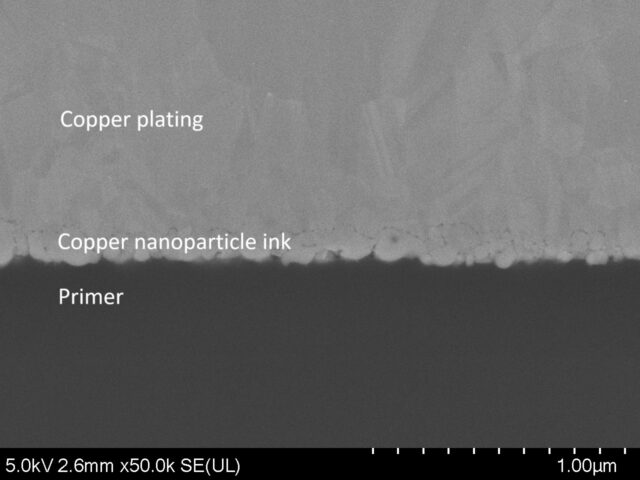

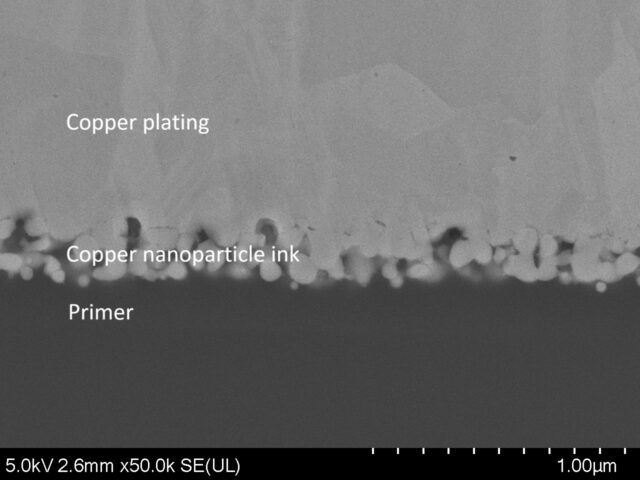

- The kick-off of mass production is enabled by the newly developed primer, which ensures both precise inkjet printing of delicate patterns and strong adhesion.

Advancing Sustainable Circuit Board Technology

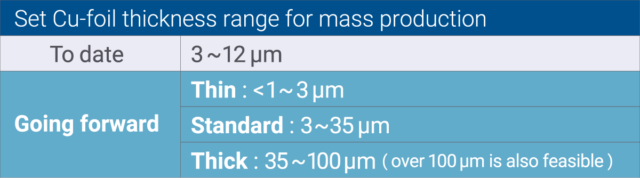

Since 2020, Elephantech has leveraged its inkjet printing expertise to mass produce SustainaCircuits™, which reduces copper usage by 70-80% compared to conventional methods. Building on its current offerings of FPCs with copper foil’s thicknesses between 3~12µm, Elephantech is proactively advancing technological frontiers to

effectively address the diverse and evolving market demands.

The recent expansion in copper foil thickness customization is driven by breakthrough innovations in materials

and processes.

Material Innovations: New Primer for Superior Adhesion and Precision

With its newly developed primer in place, Elephantech continues delivering outstanding inkjet printing precision while setting a new benckmark in adhesion strength.

This advancement supports 12.5µm polyimide substrates in addition to the current 25µm ones, contributing to a reduced overall thickness of FPC. These products are already available for development use.

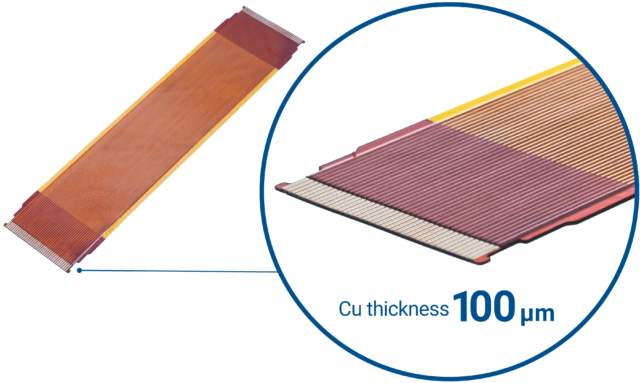

Process Optimization : Thick Copper Layers for High-Current Applications

For thick copper-foil FPCs, Elephantech has adapted its proprietary electroplating technology, which also works seamlessly with rigid multilayer circuit boards. With this newly available thickness, the additive manufacturing approach that SustainaCircuits™ uses, depositing copper only where needed, will generate greater cost advantages in reducing copper waster, compared to the subtractive approach, which removes excess copper through etching.

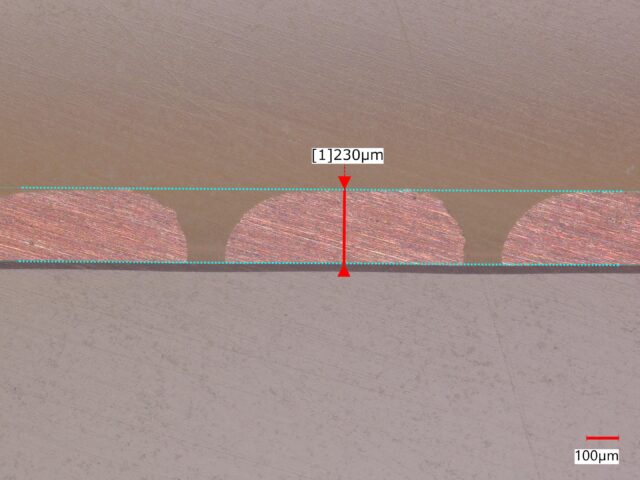

Beyond handling FPCs with standard copper-foil thickness of 18µm and 35µm, which have a large market circulation, Elephantech can now flexibly accommodate thicker copper level exceeding 35µm, meeting a wide range of custom thickness requirements. The company is currently mass-producing FPCs with copper-foils up to 100µm thick and has development capabilities reaching up to the 200µm level.

Meeting Industry Needs in Power Electronics and High-Current Applications

Thick copper-foil FPC technology is particularly beneficial for the power electronics fields such as automotive, industrial equipment, battery applications and harness replacements, where high current is essential. The ability to significantly reduce environmental impact and costs has already led to demand for replacing conventional double-sided FPCs, with several projects in progress.

For inquiries regarding thin and thick copper-foil FPCs, please contact the FPC Manufacturing Business sales team. Through continuous innovatoins, Elephantech strives to contribute to a sustainable, carbon-neutral society.

Company Overview

| Name | Elephantech Inc. |

| Establishment | January 2014 |

| Headquarters | 4-3-8 Hatchobori, Chuo-ku, Tokyo 104-0032, Japan |

| Representative | Shinya Shimizu, Representative Director & CEO |

| Business Description | Development of printed electronics manufacturing technology and provision of related services |

| URL | https://elephantech.com/en/ |

Elephantech, a startup dedicated to creating a sustainable world through the power of innovative manufacturing, is transforming the printed circuit board (PCB) industry with its proprietary metal inkjet printing technology, SustainaCircuits™.

Compared to conventional subtractive manufacturing methods, SustainaCircuits™ significantly reduces environmental impact, cutting CO₂ emissions by 75%, water usage by 95% and copper consumption by 70%.

Elephantech is committed to making this innovative technology an industry standard, contributing to a more sustainable and resource-efficient future.