Launch of the Additive Manufacturing Center (1)

- This article is more than 2 years old since it was last updated. The content may be outdated.

Hi, this is Masa from Elephantech. We established the Additive Manufacturing Center (“AMC”) in April of 2020 and, having in June welcomed Mr Kawamoto on loan from Mitsui Chemicals as the center’s director, we’re all set to start operations.

Among our existing services is the Ink Discharge Evaluation Service. Mr Saito, who is in charge of this particular service, joined us following a visit to our company on a tour organized by the Imaging Society of Japan.

As for the AMC, we’ll be focusing on 4 main themes:

1) Electronics, which is our specialty,

2) Healthcare, including biosensors, following strong demand from our P-Flex®customers,

3) Textile, following up on a previous attempt with Cemedine, and

4) Optics, which is also a strength of Mitsui Chemicals.

These 4 themes aren’t necessarily independent and there will be crossovers. For instance, there are many areas in the healthcare field which involves electrodes, and so we could also consider it from an electronics standpoint. In this article I’d like to share with you a little story about how Elephantech came to be involved with biosensors.

From then till now and into the future

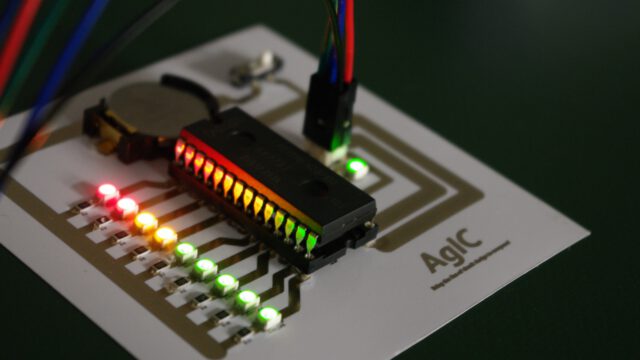

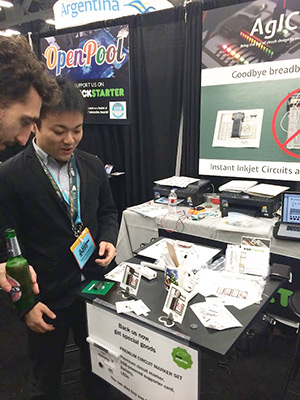

At our origine, back when our company was still known as AgIC, we sold products that converted household inkjet printers into circuit printers. Looking back on it even now, I still feel that our Kickstarter video gives a sense of “new experience”.

Circuits being printed with a simple Ctrl + P from a printer that is safe, doesn’t produce waste and could fit on top of a desk; that vision we had, the maker’s dream, has yet to be fully realized. The concept of DTP came to be in the 1980s and, in my opinion, led to the birth of a variety of businesses and cultures.

Although FDM 3D printers have become rather common in recent years following the expiration of an important patent, we can argue that its democratization as a manufacturing equipment has only just started through its incorporation in a number of industrial printers. What I find intriguing is that 3D printers were also invented in the 1980s, around the same time as DTP.The first patent was filed in 1986, and the patent for the FDM-type printer was filed in 1989. The world has moved on since then, but I feel like so much has happened in the past 10 years since the patent for the FDM-type printer expire in 2009.

Our company was established in 2014, and I think we were strongly influenced by Form1’s Kickstarter campaign in 2012.

In fact, we used Form1’s initial lot of products but found the laser to be way too weak and it was really a struggle back then.The Form3 we use now is a completely different story and it works just wonderfully. Form3 is still too expensive for it to be considered for home usage, but we’re really pleased to see a machine that is capable of such high-precision 3D prints being made so easily available by a venture that started, like us, from a Kickstarter campaign.

That’s why Elephantech as a company continues to involve itself in this culture, be it the Maker Movement that started in 2010 or crowdfunding or University research (the research conducted by the Kawahara Laboratory of Tokyo University was essential in the birth of our company). And so we regularly read all sorts of research papers, and we’ve come to realize that there is one key word that keeps popping up in the research conducted by searchers who continue to hack home printers to take on various challenges (we really resonate with your work!) That key word is biosensors.

In the next post, I’d like to write about biosensors in more detail.