Developed adhesive coating technology for advanced packaging using high-precision inkjet technology

Elephantech’s inkjet technology opens new possibilities for semiconductor manufacturing

Elephantech has developed and launched NeuralJet™, an innovative inkjet manufacturing technology that uses AI to learn and correct for individual variations and inaccuracies, delivering unmatched precision. Building on this breakthrough, Elephantech has introduced an inkjet-based method for applying bonding materials essential for advanced packaging, such as those used in AI semiconductors.

In advanced packaging, as represented by AI semiconductors, the increase in the density of two-dimensional semiconductors is reaching its limits, and three-dimensional packaging is becoming necessary. For three-dimensional stacking, bonding materials are essential, but conventional coating methods such as spin coating make it difficult to achieve complex coatings like applying the material only to specific areas, applying multiple thicknesses simultaneously, or coating surfaces with steps. Inkjet technology can realize these tasks, but general inkjet devices have faced challenges in terms of precision, and there have been no practical applications in advanced packaging until now.

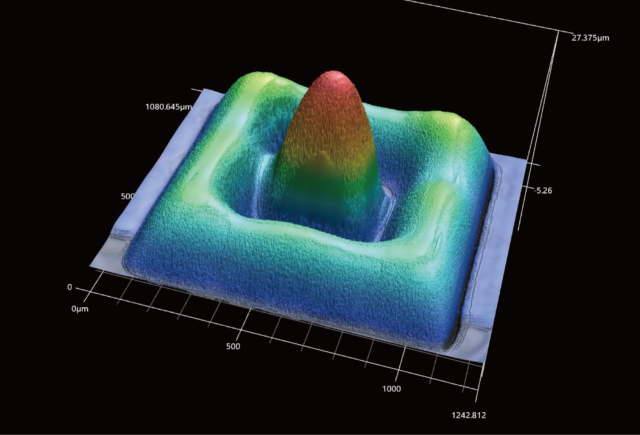

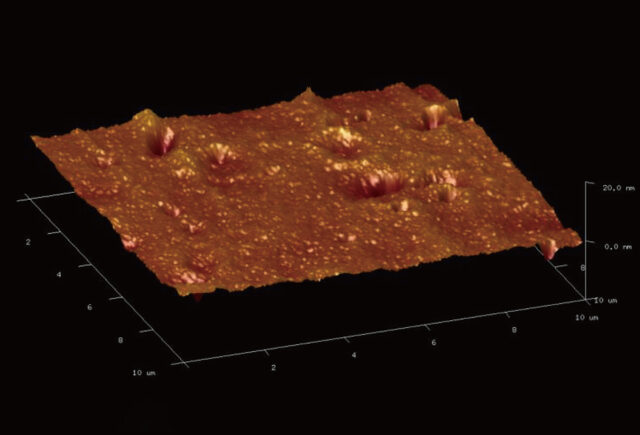

The ELP04, a new inkjet device equipped with our Neural Jet technology, uses AI technology “Neural Jet” to control the landing of inkjet ink droplets on a one-drop basis, achieving an extremely smooth coating film. In coating on wafers, it achieves an extremely smooth coating with a Ra (surface roughness) of 0.8 nm (Appendix 1). Similarly, in another sample, it achieves film thickness control in the sub-μm to tens of μm range (Appendix 2).

With this technology, it will be possible to apply bonding materials of the required thickness only to the required areas in a highly smooth state, and it is expected to greatly increase the flexibility of advanced packaging methods.

Elephantech has also introduced the ELP04 PILOT, a high-precision inkjet system designed to facilitate advanced packaging coating processes. As a compact, high quality inkjet system, the ELP04 PILOT supports the development of new materials and the optimization of manufacturing processes, extending its applications beyond the bonding of materials.

We believe this technological advancement has the potential to significantly improve the efficiency and sophistication of semiconductor manufacturing processes, particularly in the development of AI semiconductors and advanced packaging.

This groundbreaking innovation has the potential to revolutionize semiconductor manufacturing, driving efficiency and precision while accelerating advancements in AI semiconductors and cutting-edge packaging technologies.

1: Application of high-heat-resistant adhesive to wafers using inkjet technology

(Material provided by Mitsui Chemicals, Inc.)

This is an innovative inkjet application technology that makes possible processes that were previously difficult to achieve, such as controlling the thickness of the film in each area and selective patterning of where to apply the adhesive and where not to apply it. This dramatically improves the flexibility of semiconductor manufacturing and contributes to reducing the environmental impact.

Key Features

1: Inkjet technology makes it possible to control the thickness of the film in each area when applying the adhesive.

2: Inkjet technology makes it possible to pattern the areas to be coated and the areas not to be coated.

3: Achieves low Ra (surface roughness) and can be applied as an advanced packaging and post-processing coating technology.

| Localized change in film thickness | Ra (surface roughness): 0.8 nm |

|---|---|

|

|

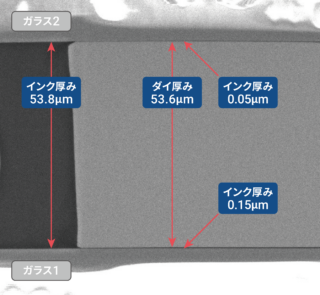

2: Inkjet Coating of Heterogeneous Adhesives for advanced packaging and Silicon Photonics

(Material provided by Mitsui Chemicals, Inc.)

Inkjet technology has been used to achieve the coating of heterogeneous materials such as glass and silicon, as well as three-dimensional structures. The local control of film thickness and high robustness against step differences support further advancements in packaging.

Key Features

1: Inkjet coating has realized the bonding of heterogeneous materials such as glass-to-glass and glass-to-die, as well as three-dimensional bonding.

2: Local control of film thickness at the sub-μm to several tens of μm level has been achieved, contributing to further advancements in packaging.

3: High robustness against step differences makes it suitable for the installation of dummy silicon and silicon bridges within packages.

■ Cross-Sectional Diagram

For more information, please contact us using the form below. We will propose a solution tailored to your needs.