Elephantech Launches Copper-on-Copper Self-Assembled Nanoparticles

– Unlocking New Possibilities in Semiconductor Packaging Materials –

Tokyo, Japan – December 22, 2025 – Japanese deep-tech startup Elephantech Inc. today announced the successful development of Self-Assembled Copper Nanoparticles (SA-CuNP), a breakthrough technology that imparts dispersibility to copper microparticle pastes through an entirely new mechanism.

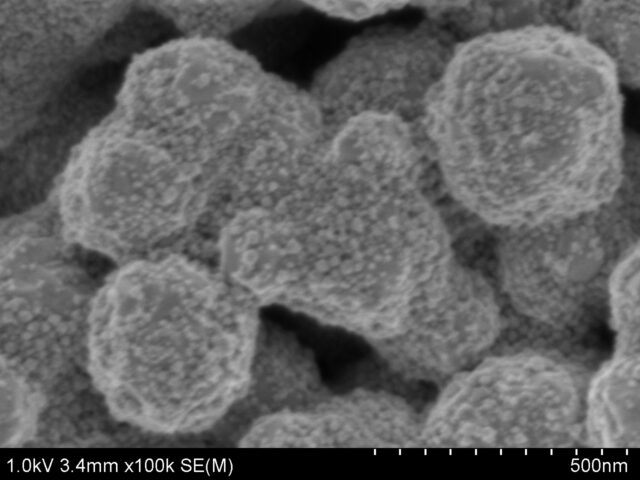

SEM image capturing the self-assembly behavior of SA-CuNP

SEM image capturing the self-assembly behavior of SA-CuNPIn recent years demand for metal sintering materials has been on sharp rise, especially in the power semiconductor field. Among the metal material candidates, copper pastes, offering lower cost and higher reliability than silver, have shown the most potential.

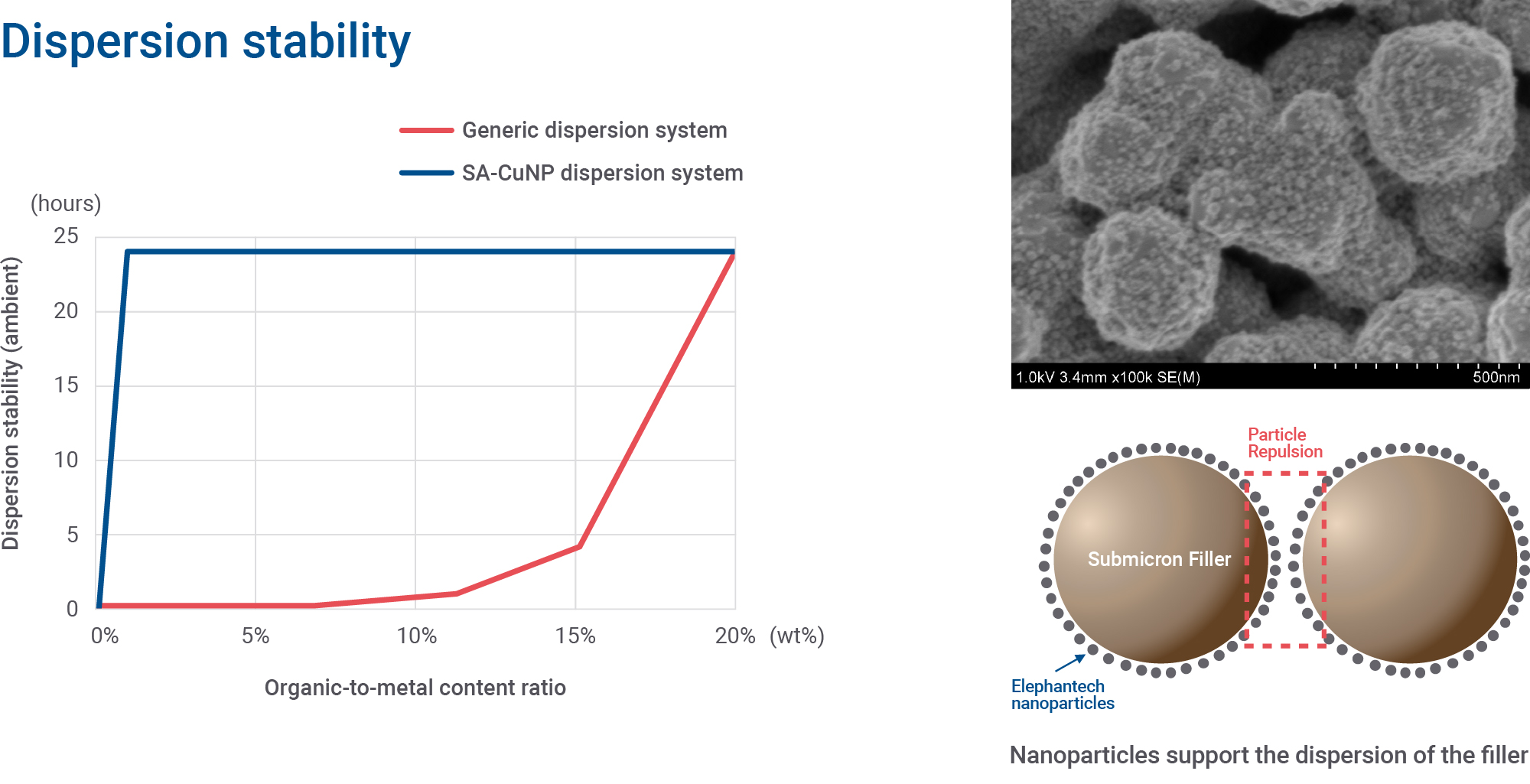

However conventional copper pastes rely on organic dispersants to stabilize particles, which often leads to reduced metal content, inhibited sintering and lower conductivity, posing limits to broad application.

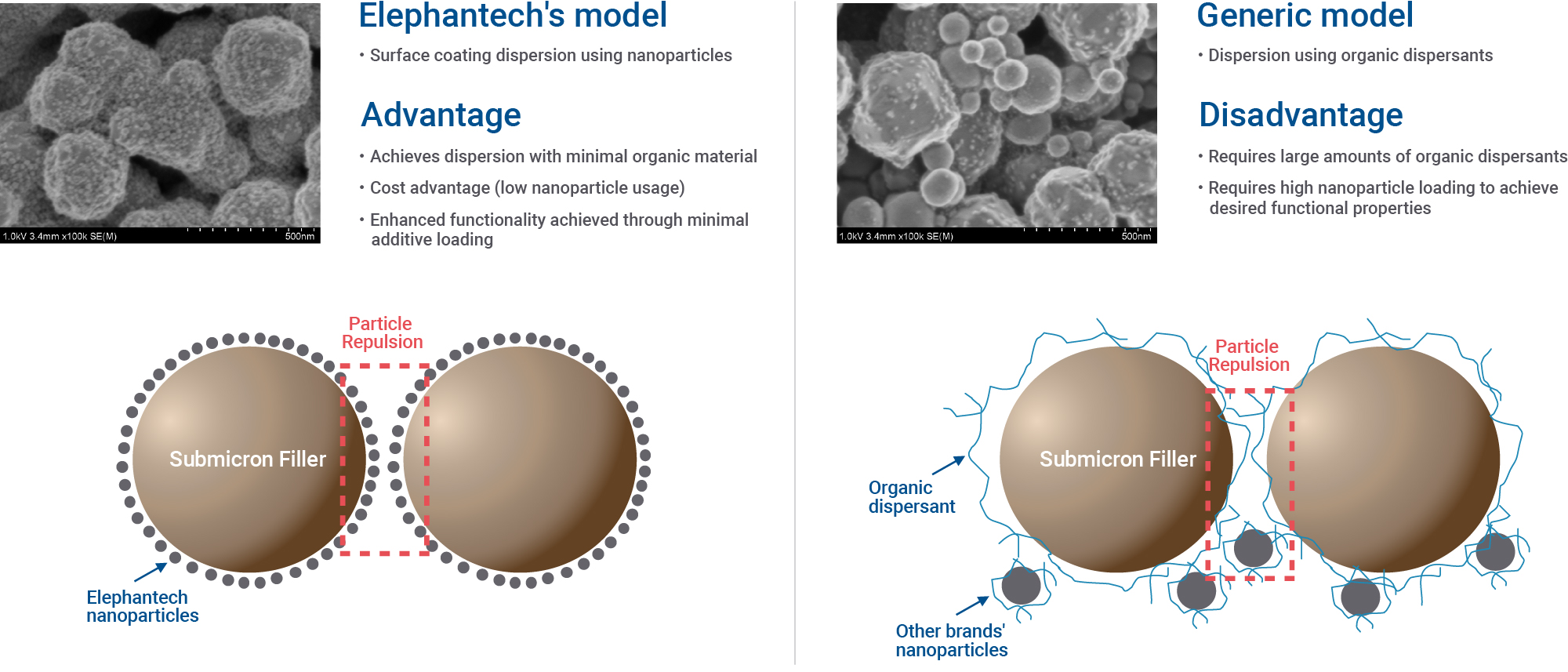

Elephantech’s SA-CuNP technology overcomes the limitations by enabling copper-to-copper dispersion without depending on organic dispersants.

While previously mechanochemical methods have been introduced to attach one metal particles to the surface of another, now SA-CuNP provides a greatly simplified process: mixing the designated copper nanoparticles with copper microparticles will make the nanoparticles spontaneously assemble into a uniform, continuous layer on the microparticle surface.

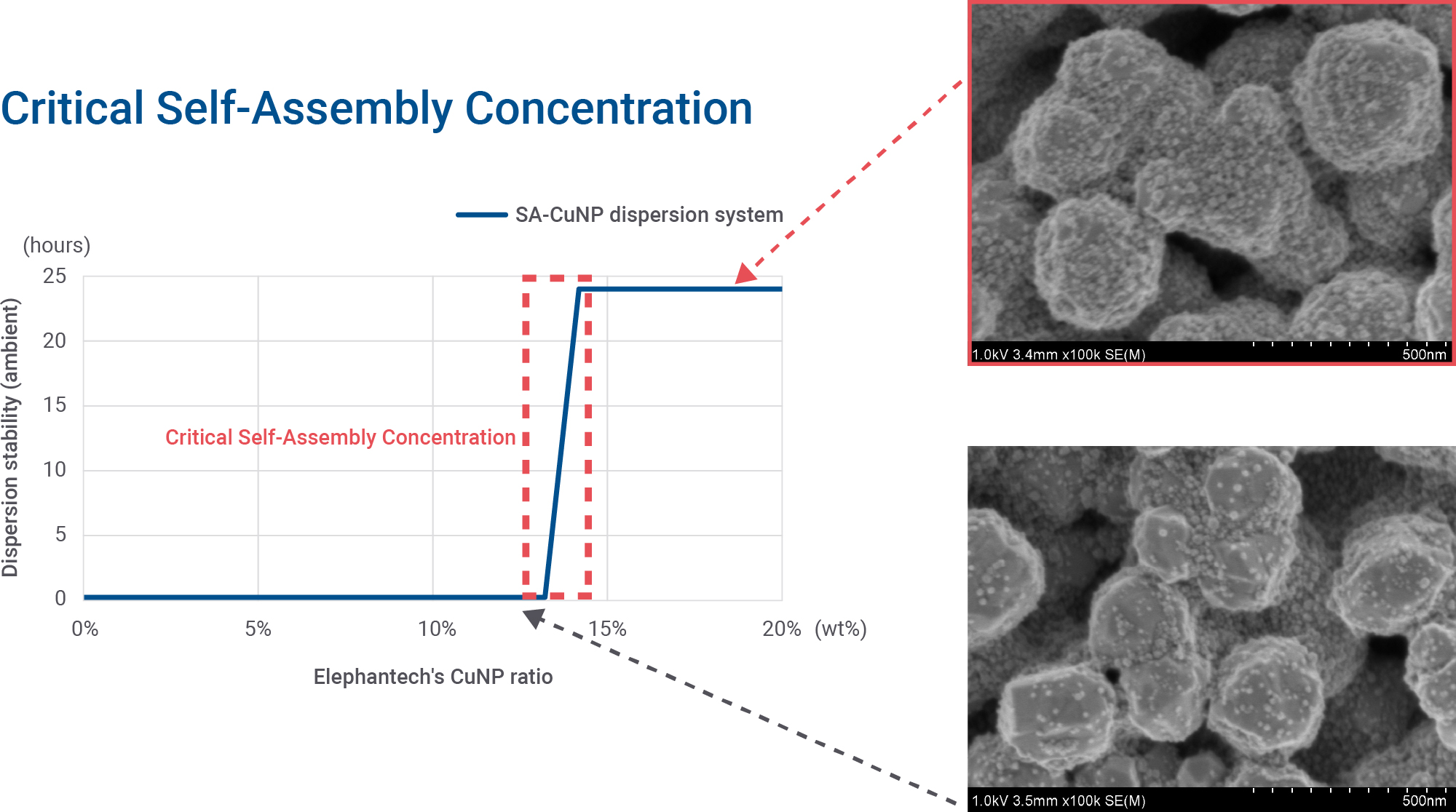

SA-CuNP also exhibits a unique behavior: once its concentration exceeds a certain level, self-assembly is rapidly triggered. Elephantech defines the threshold as Critical Self-Assembly Concentration (CSAC), a concept similar to Critical Micelle Concentration (CMC). Above CSAC, dispersion stability increases dramatically, enabling higher-performance paste formulations.

Dispersion formulation stability comparison: SA-CuNP VS generic

Dispersion formulation stability comparison: SA-CuNP VS genericKey Merits

SA-CuNP enables innovative copper paste design using organic dispersants of unprecedented low molecular weight and at low minimal loading, releasing huge freedom in engineering material properties, particularly in sintering behavior and viscosity tuning.

With lower amount of organic components, enhancement across key metrics can be expected:

– higher metal loading

– improved sinterability, electrical conductivity and thermal conductivity

– reduced gas generation and residue during curing

Commercial Applications

SA-CuNP majorly supports copper paste manufacturers and materials producers to expand product and technology portfolios. Elephantech’s offerings include:・licensing of proprietary dispersion technology

・joint development of optimized pastes formulations

As the manufacturing process of SA-CuNP has already been stabilized, Elephantech is scaling production capacity toward mass-production level supply.

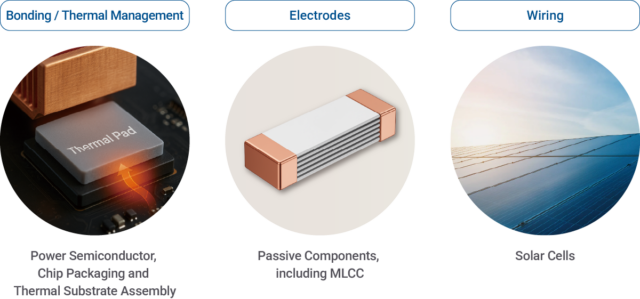

Application Cases

SA-CuNP is expected to contribute to a wide range of advanced electronics applications:

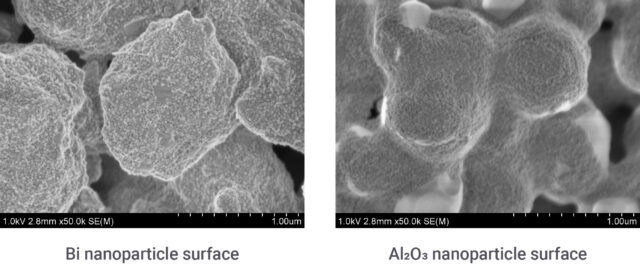

Elephantech is advancing SA-CuNP beyond copper into a general-purpose nanoparticle self-assembly platform that is applicable to various inorganic microparticles.

SEM image capturing the self-assembly behavior of SA-CuNP for various inorganic microparticles

SEM image capturing the self-assembly behavior of SA-CuNP for various inorganic microparticlesFurthermore, SA-CuNP’s similar self-assembling behavior on Bi and Al2O3 particle surface has been confirmed, suggesting future applications in controlled dispersion of resin composite materials and improved flowability of high-filler loaded materials.

Building on the launch, Elephantech remains committed to unlocking the potential of new nanomaterials.

Business Development Unit

bd@elephantech.co.jp

Related Brochure Download

Materials_Copper_Nano Filler

Company Overview

| Name | Elephantech Inc. |

| Establishment | January 2014 |

| Headquarter | 4-3-8 Hatchobori, Chuo-ku, Tokyo 104-0032, Japan |

| Representative | Shinya Shimizu, Representative Director / CEO / Founder |

| Business Description | Development, manufacture and sales of proprietary machinery and materials, as well as PCB products |

| URL | https://elephantech.com/en/ |

Public Relations Department: pr@elephantech.co.jp