Launch of the Additive Manufacturing Center (2)

- This article is more than 2 years old since it was last updated. The content may be outdated.

Hi, this is Masa from Elephantech.

I’d like to follow up on my last article in which I touched upon how we regularly read all sorts of research papers and how we’ve come to realize that there is one key word that keeps popping up in the research conducted by searchers who continue to hack home printers to take on various challenges (we really resonate with your work!) That key word is biosensors.

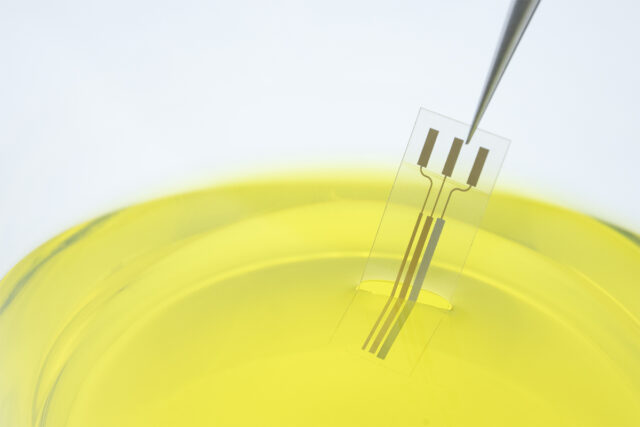

Looking at various research papers on biosensors, we quickly realized that many of them had printed electrodes using carbon or silver paste and that it seemed possible to print using an inkjet printer, and so our first step was to create a manufacturing service for eletrochemical sensors. Of course, we could have just painted over with gold paste or ink, but we possessed plating technology and thought that we would be able to provide all kinds of values by adding gold plating and the like to the mix.

Electrochemical sensors for biosensors

These metal electrodes we refer to as electrochemical sensors for biosensors can generally come in 3 forms; working electrodes, reference electrodes and counter electrodes.I have no doubt that many of you are intrigued and curious about how these work and especially about the mechanisms of the reference electrodes. While an in-depth explanation merits its own separate article, suffice to say that silver/silver chloride electrodes (Ag/AgCl) are frequently used as reference electrodes. At Elephantech, the silver/silver chloride electrode pattern is formed by silk-screen printing a silver chloride paste. We are in search of an inkjet ink with a silver + silver chloride filler mix, but silver chloride particles seem to coagulate easily and we have yet to come across a finished commercial product. Should anybody reading this article know of a silver/silver chloride ink for inkjet printing or happens to be developing such a product, we would be really grateful if you reached out to us.

Anyway, as we went around seeing our customers with these gold electrodes and silver/silver chloride electrodes, there was increasing demand from a section of our customers for an enzyme treatment besides the electrodes. This applies to the Detection section below. (As a side note, the research paper cited below is extremely well put together and will be making frequent appearances in the future.)

https://www.researchgate.net/publication/275583905_Inkjet_printing_for_biosensor_fabrication_Combining_chemistry_and_technology_for_advanced_manufacturing

Towards the Establishment of the AMC

The reason behind the demand for enzymes to be printed by inkjet printing is that the properties of the enzyme requires it to be dried at a very low temperature as it will be inactivated if heated and dried too much. As such, when applying multiple enzymes, the drying process becomes rather complex.Inkjet printing on the other hand allows for contactless printing and multiple inks can be printed onto the designated spot without having to wait for the ink to dry.And so we were made aware of how there were other applications for inkjet printing but, as a company that prints electronic circuits, we were unsure as to whether we should take on a business that was unrelated to circuit board printing.And then again, one of our company’s strengths was in how we stabilized the inkjet printing of silver nano ink, which is extremely difficult to discharge, by combining ink, printhead and equipment and bringing it all to a mass-production level. In other words, our company’s strength lies in our ability to allow “complex materials” to be printed by inkjet printing.Following that logic, we came to think about how we shouldn’t be limited to silver nano ink.In the first place, regarding our company’s circuitry business, we had already started experimenting with Cu taking into account the high probability for a future shift from silver nano ink to copper ink for cost-saving purposes. Realizing that expanding into the discharge of inks other than silver nano ink represented an opportunity for our company to provide value in answer to a greater spectrum of society’s needs, we started down the path towards the establishment of the AMC.

In my following posts, I would like to delve deeper into whether inkjet is really useful for manufacturing biosensors and in what ways it is advantageous.