【Ink Discharge Evaluation Service blog : 2】Video presentation of Epson’s inkjet machine for R&D purposes.

- This article is more than 2 years old since it was last updated. The content may be outdated.

Here is an overview of Epson’s inkjet machine for R&D purposes used for our Ink Discharge Evaluation Service.

Epson’s inkjet machine for R&D purposes is equipped with an ink droplet flight path observation function and a printing function. The flight path observation function controls the camera and light source at high speed to capture images of the ink droplets in real-time as they are ejected from the printhead. Epson’s inkjet machine for R&D purposes is also compatible with more specialized evaluations that require voltage adjustments and waveform adjustments. While the initial ink discharge evaluation service is generally provided free of charge, extra fees shall apply to highly specialized evaluations and Print Evaluation.

With the ink discharge evaluation service, Elephantech will use its knowledge in inkjet printing technologies and Epson’s PrecisionCore to evaluate ink characteristics.

An added advantage for users is that the service makes it easier to visualize a path towards mass-production.

Collaborating with Elephantech can also contribute to achieving Sustainable Development Goals (SDGs) as the company has a proven track record in developing mass-production processes and is a proponent of environmentally friendlier manufacturing methods for mass-production.

From the video

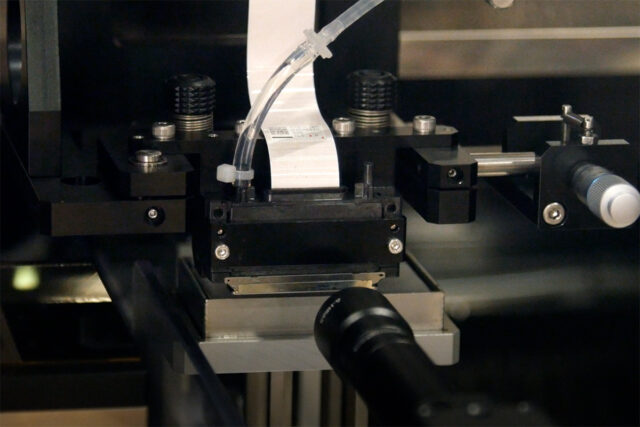

This is the insides of the inkjet machine for R&D purposes made by Epson. The moving part is the inkjet printhead. In front is the observation camera. In the rear is the light source.

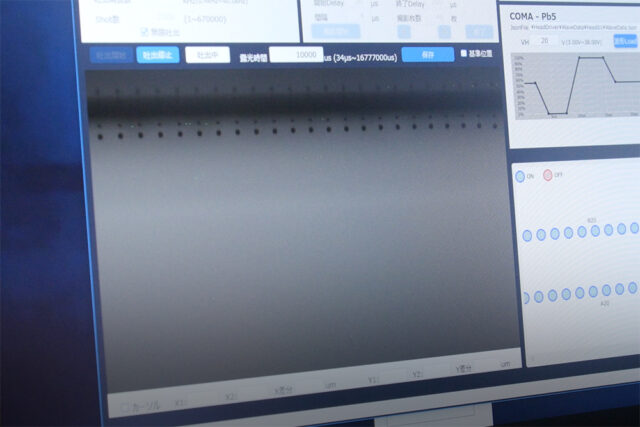

Ink droplets discharged by the printhead can be observed in real-time.

By emitting extremely short flashes of light to match the timing of the ink discharge, the shadows of the ink droplets can be clearly captured.

In-flight ink droplets are shown as black spheres on the machine’s monitor.

Approximately 20 nozzles can be observed at the same time on a single monitor.

All nozzles on a printhead can be observed by moving the printhead.

The ink discharge evaluation will be made using this machine. The built-in functions can be used to adjust waveforms and perform various evaluations.

Outline of Epson’s Inkjet machine for R&D purposes

| Manufacturer | Seiko Epson Corporation |

| Printhead | PrecisionCore |

| Ink viscocity guide | 1-10 mPaS (Please contact us if not within this range.) |

| Minimum required ink volume | 50 mL |

| Observation functions | Ink droplet flight Printing |

| Printing function | Print on 100mm square stage |

| Ink type | Water-based and solvent-based inks |

| Evaluation | Evaluated by Elephantech under commission from Epson |