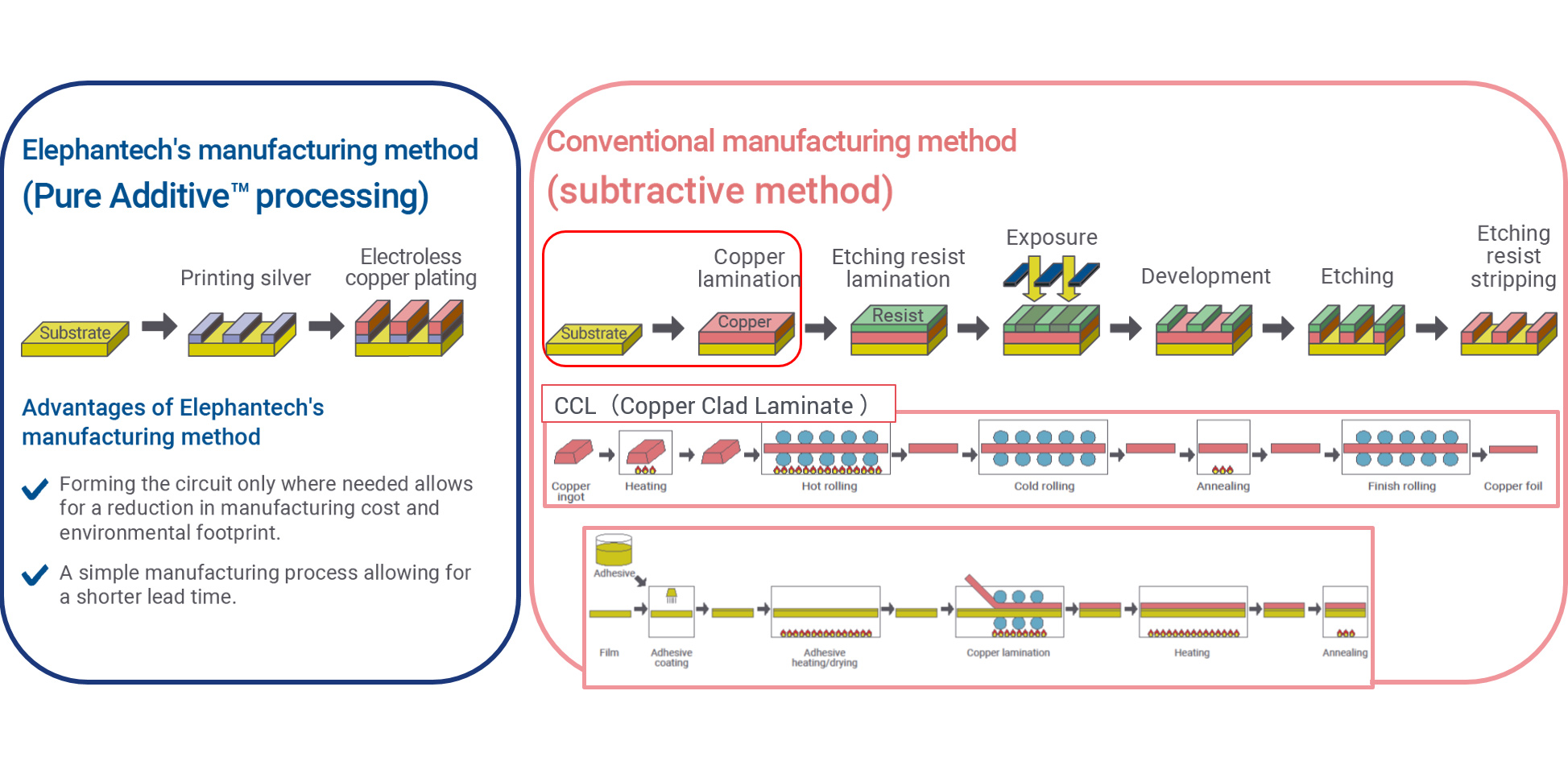

The future of electronics:Shifting from "dissolving unnecessary parts" to "printing onto necessary parts"

- This article is more than 2 years old since it was last updated. The content may be outdated.

About Elephantech’s manufacturing method (Pure Additive™️ production)

Taking the example of printed circuit boards, the conventional manufacturing method was an extremely long process in which copper foil is manufactured, laminated with film (production of CCL), and laminated with photosensitive materials before the desired copper pattern is achieved by dissolving and discarding the copper foil from unnecessary parts by exposure, development and etching.

Our process achieves the desired copper pattern by printing the metal onto film and growing it, not only forgoing the need for copper foil manufacturing and CCL manufacturing processes but also eliminating the need for the etching process to dissolve and discard the copper foil.

Before:「Etching unnecessary metal」 →Lot of waste.

Now :「Print the metal you need」 →There’s no waste.

Elephantech’s efforts to Reduce Environmental Impact byPure Additive™️ production;

・Reducing the consumption of natural resources

・Reducing water consumption

・Reduction of waste

Contributing to the SDGs’ following goals:

Goal 6:Ensure availability and sustainable management of water and sanitation for all

・6.3 、6.4

Goal 12:Ensure sustainable consumption and production patterns

・12.2 、12.5