News

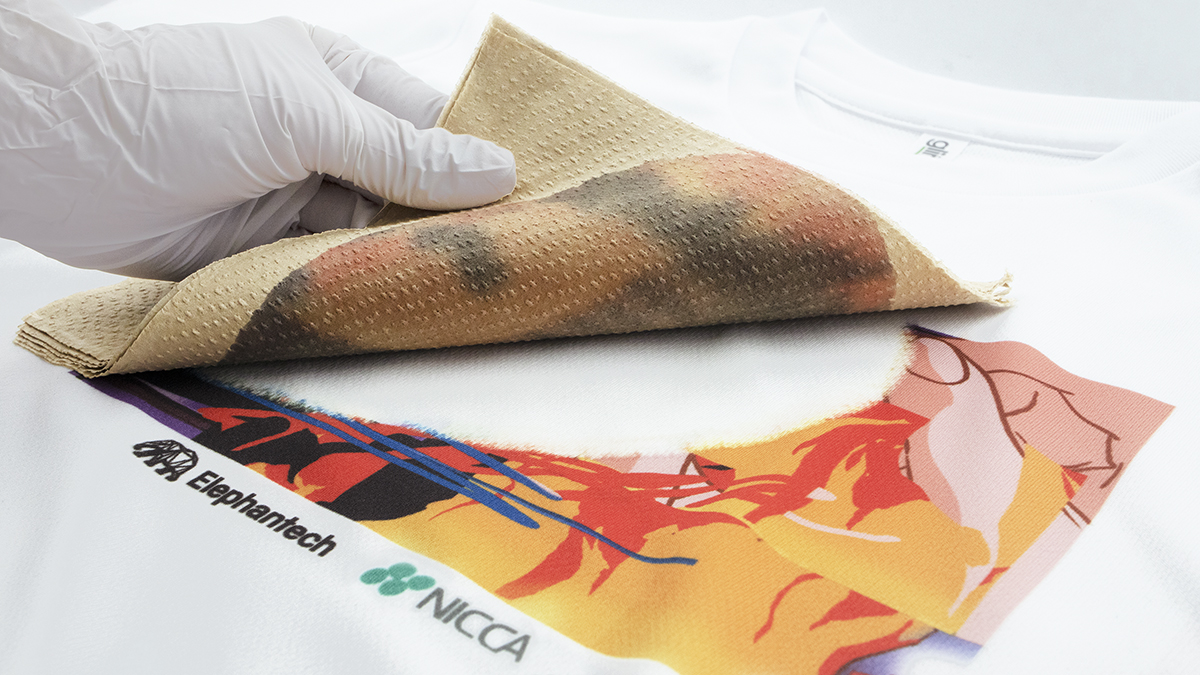

[Media Coverage] The technical trial of Neochromato process was introduced in "GREEN WORK HAKUBA vol.4".

GREEN WORK HAKUBA vol.4, a co-creation program to think about a sustainable and “fun” future based on the “Circular Economy,” was held in Hakuba Village, Nagano Prefecture, from July 27 to 29, 2022. The GREEN WORK HAKUBA page introduced a hands-on experience of Elephantech’s Neochromato process technology. GREEN WORK HAKUBA/CDS.

【Video】Elephantech: Company Introduction by CEO 2022

To help you better understand Elephantech’s business, here is a video in which CEO Shinya Shimizu explains the company’s technologies and strategies in an easy-to-understand manner. If you are interested, please feel free to contact us! Contact information for alliances, partnerships, etc. ir@elephantech.co.jp Elephantech: Company Introduction by CEO 2022(9:32)

Focus NEDO No.82 Special Edition NEDO Startup Future

Our company was featured in “Focus NEDO” No.82 published by NEDO* as a noteworthy start-up company that continues to grow toward the future. *NEDO: National Research and Development Agency New Energy and Industrial Technology Development Organization

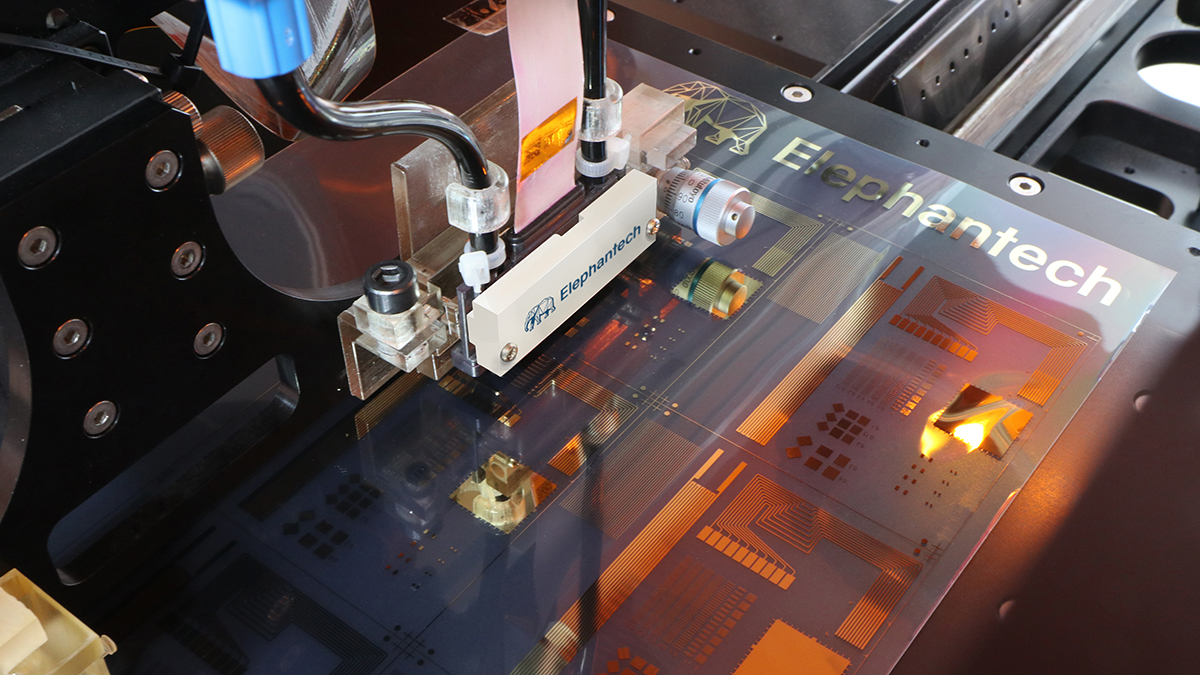

Large-scale mass production demonstration base (AMC Nagoya)

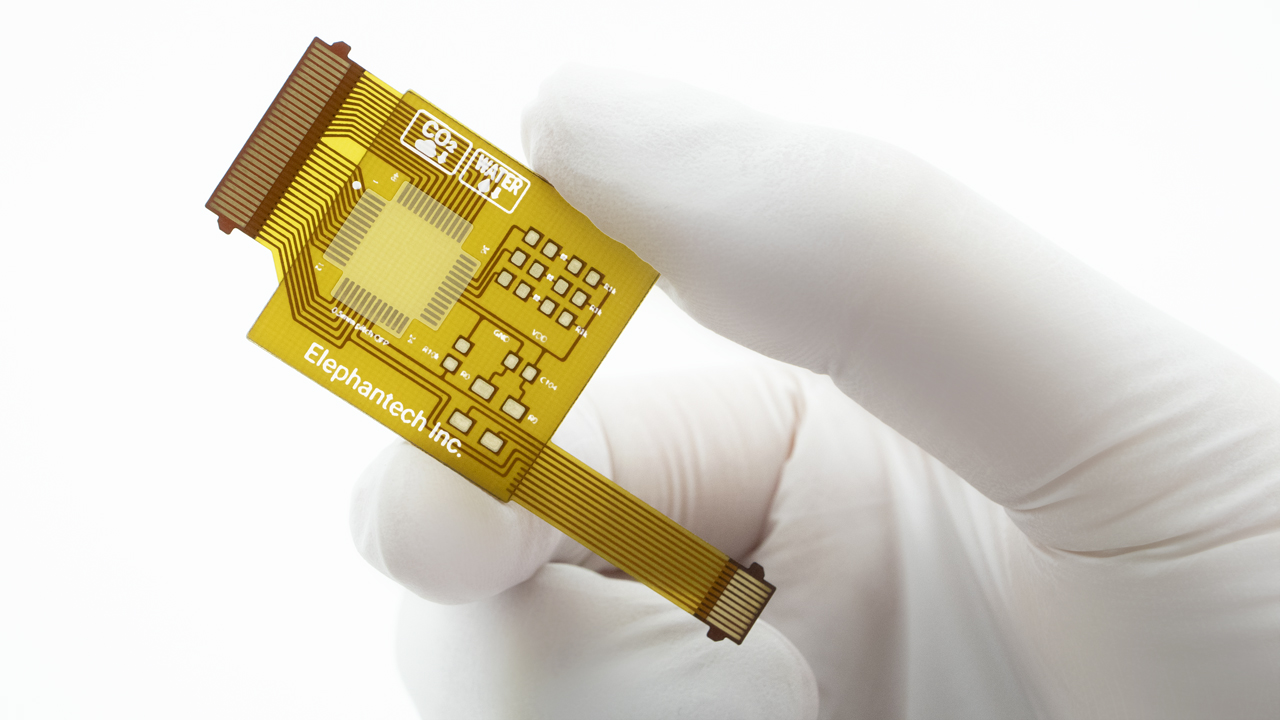

Having raised a total of JPY 1.8 billion in October 2019 and established a large mass-production and research complex within the Nagoya factory rented from Mitsui Chemicals Co., Ltd. since July 2020, we started production and shipment of mass-produced products in April 2021.

JVA2021 Award Ceremony: A short speech by our CEO, Shinya Shimizu.

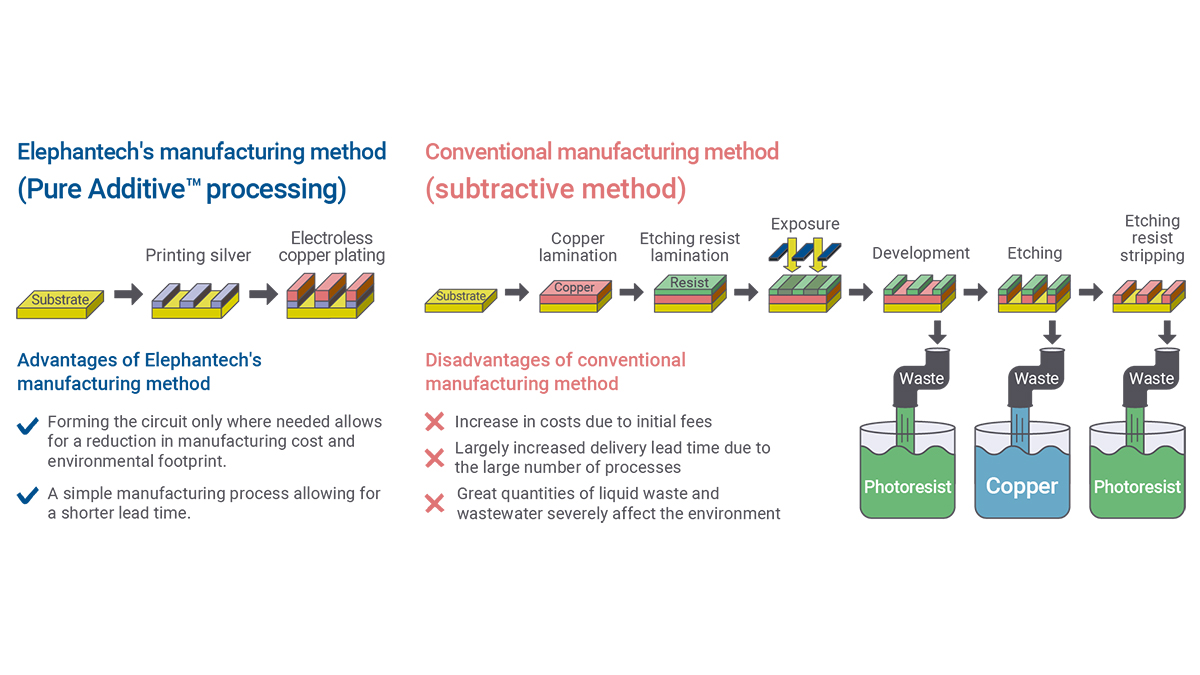

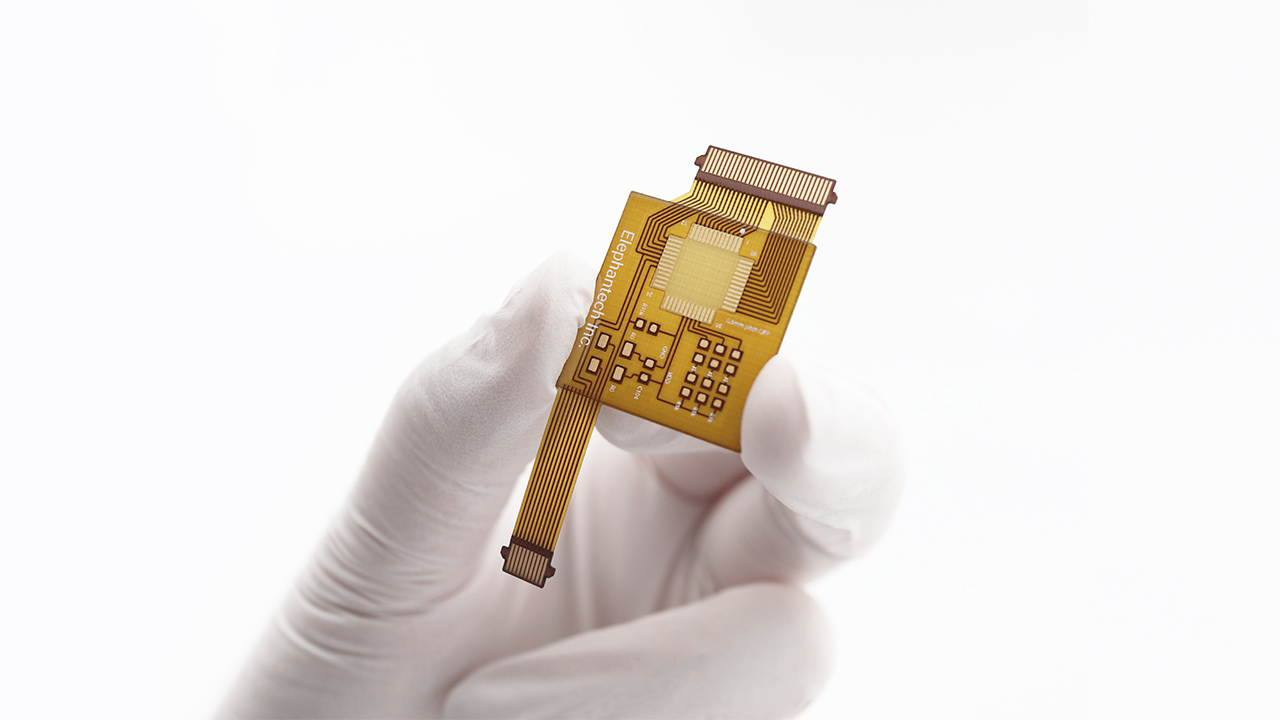

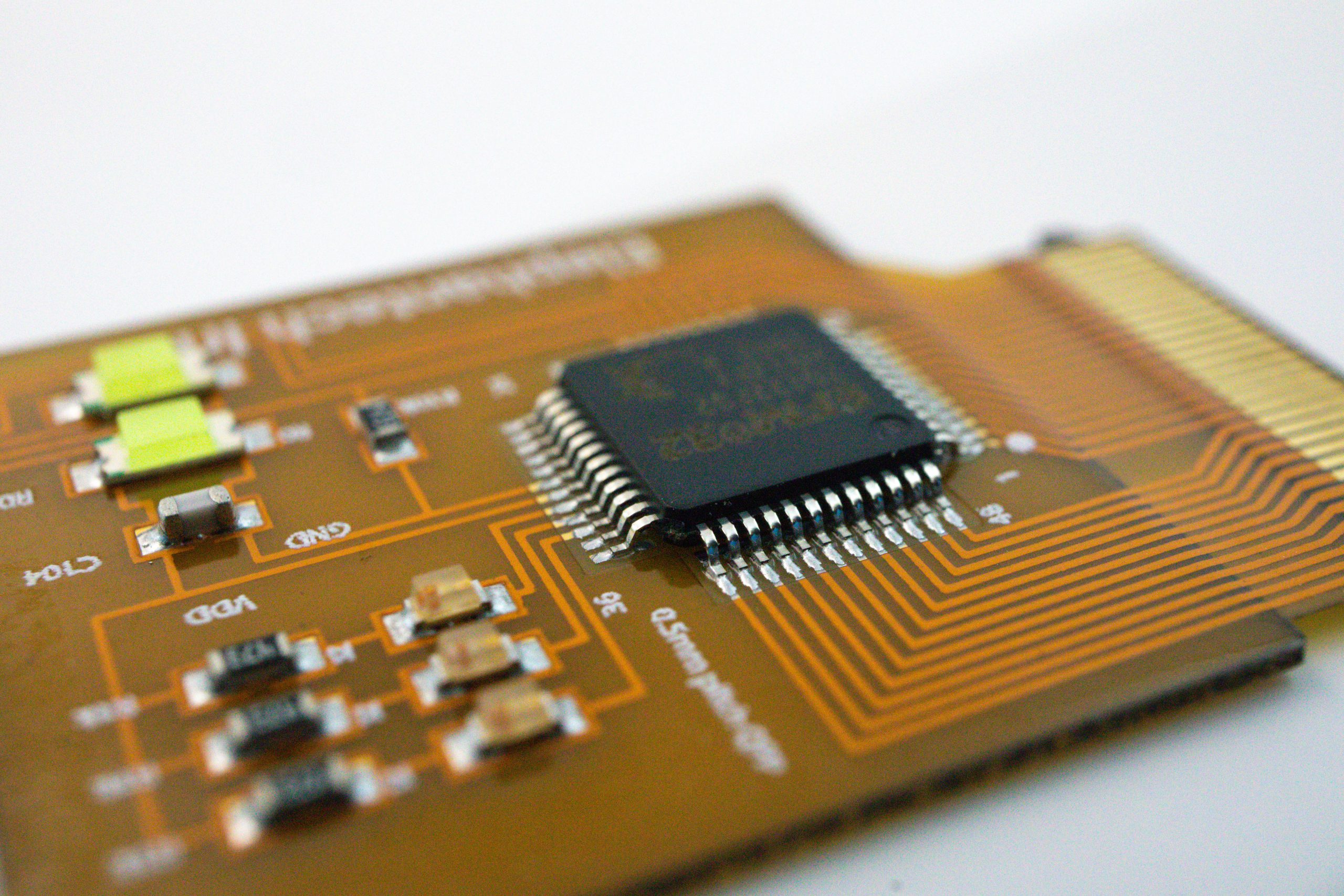

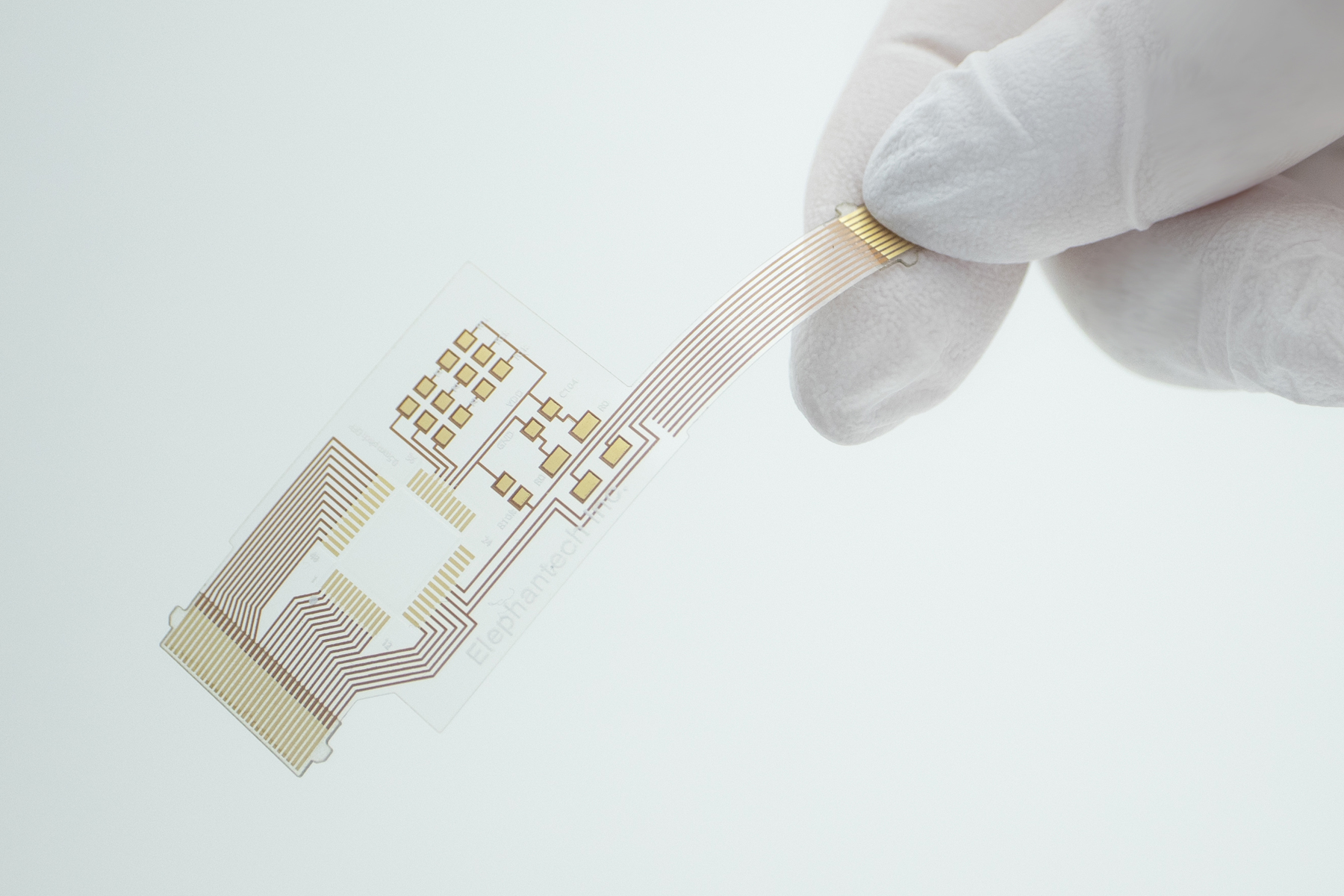

Here is a short speech from our CEO, Shinya Shimizu, at the “Japan Venture Awards 2021” ceremony held on March 1. At Elephantech, we develop mass production technologies that are environmentally friendlier and have succeeded in cutting the environmental impact caused by the manufacturing of our electronic circuits by more than 90%. The electronics industry continues to grow rapidly on the back of global trends such as IoT and 5G. Under such circumstances, the industry’s impact on the...