News

Selected for the "Global Sustainability Accelerator powered by Creww | Google for Startups."

Elephantech announces that it has been selected for the “Global Sustainability Accelerator powered by Creww | Google for Startups”, a program that aims to help sustainability-driven Japanese startups solve social issues around the world.

Elephantech Wins Best Business Practices Award at the EcoBalance International Conference

Tokyo, Japan - Elephantech Inc. ("Elephantech") won the EcoBalance Award for the Best Business Practices at the 15th Biennial International Conference on EcoBalance held at Fukuoka Convention Center from October 30 to November 2.

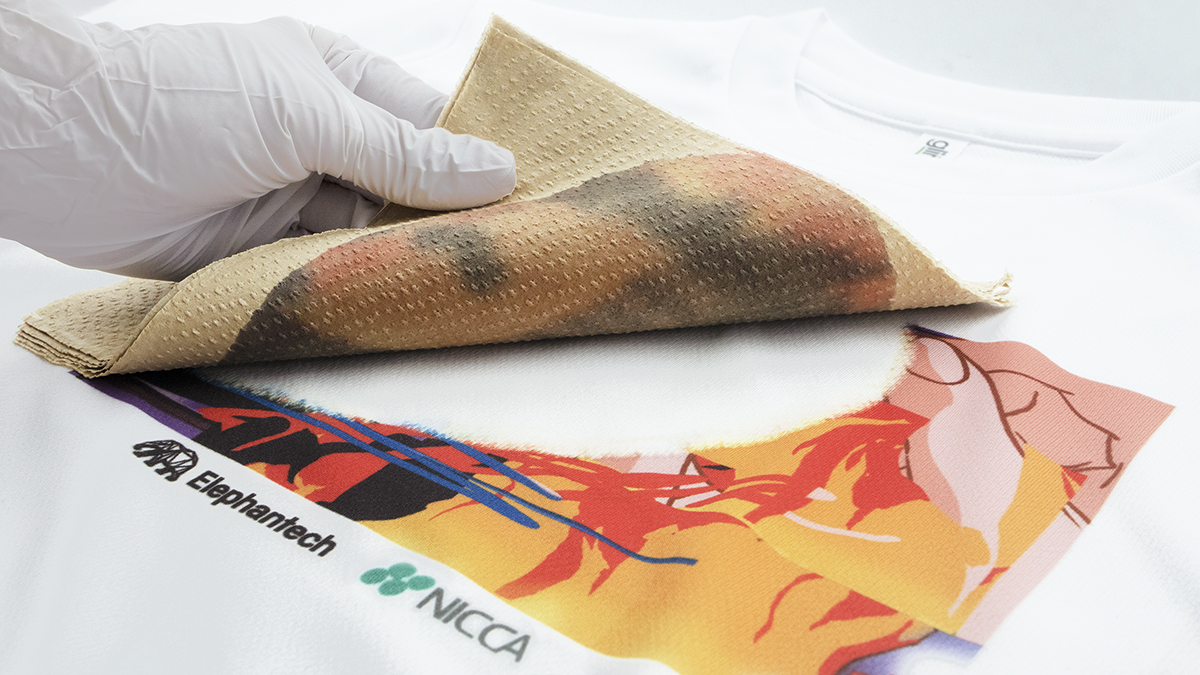

Polyester Fabric Decolorization Technology for Textile Reuse

“Neochromato Process” wins crQlr Awards

Elephantech Inc. has won the “Decolor Without Waste Award” at the “crQlr Awards,” an international competition for products and ideas that design a circular economy. Elephantech and NICCA CHEMICAL CO., LTD. won the “Decolor Without Waste Award” at the “crQlr Awards” for the “Neochromato Process”, a polyester textile decoloring technology that enables the reuse of garments by changing their colors and patterns.

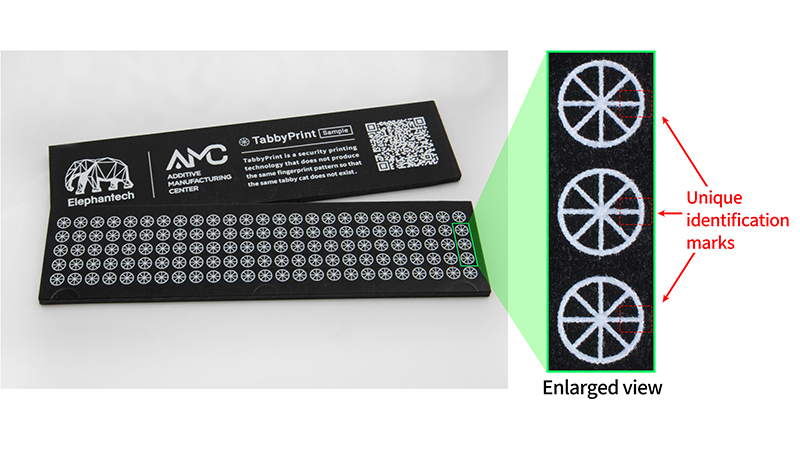

TabbyPrint Selected for Print Production of Artist Aguri Sagimori’s “MMMME” Artwork

Tokyo, Japan — Elephantech Inc. (“Elephantech”) announced that the company’s TabbyPrint technology which allows inkjet printers to print “unique, one-of-a-kind, individual identification patterns” has been selected by the artist Aguri Sagimori for the print production of her “MMMME” artwork. The collaboration is part of Elephantech’s market verification activities for its new technology. Through this project, TabbyPrint printed materials will be created, exhibited, and sold for the first time.

Elephantech Develops “TabbyPrint,”

a Unique identification marks Printing Technology

That Can Be Linked to Blockchain and Ensures Traceability.

Elephantech Inc. has developed "TabbyPrint," an inkjet Unique identification marks Printing Technology that can print directly on objects. Since this technology is expected to be used with blockchain to ensure traceability and other applications, Elephantech will begin proof-of-concept (PoC) activities.