Elephantech Publishes Quantitative Evaluation of Life Cycle Assessment Based Reduction in CO2 Emission and Water Consumption

- This article is more than 2 years old since it was last updated. The content may be outdated.

Elephantech Inc. (“Elephantech”) is pleased to announce that the company has published an estimate on LCA-based reductions in 1) CO2 emission, 2) water consumption, and 3) toxic substances when using the company’s Pure Additive™ production as compared to conventional PCB manufacturing methods.

For more information, please click here. ▶ Environmental results

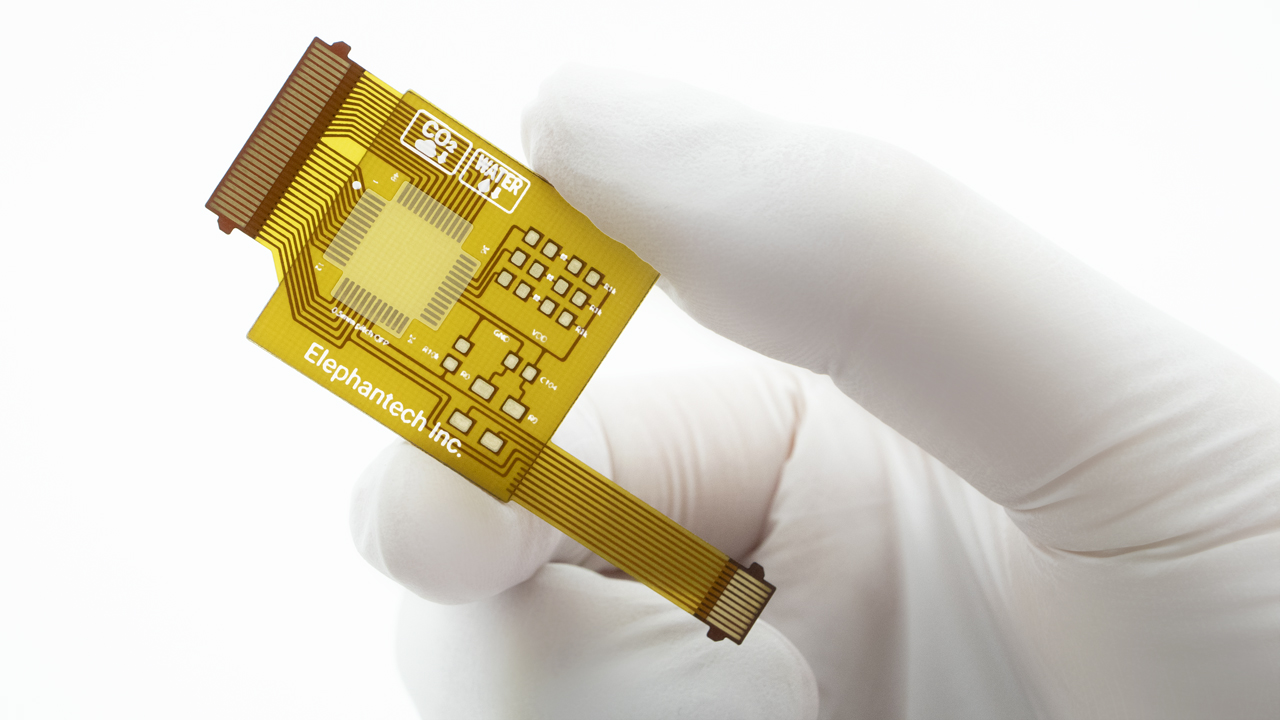

Our P-Flex® PI Sample

【Background】

As can be seen with the Sustainable Development Goals (SDGs), environmental friendliness and conservation are gaining traction as global concerns. Amid such global trends, Elephantech believes it is an important corporate responsibility to disclose information on a company’s environmental strategy and has created data visualization to highlight its efforts towards reaching sustainability.

【Results of the quantitative evaluation of environmental impact conducted by Elephantech】 Comparing conventional PCB manufacturing methods to Elephantech’s Pure Additive™ production, the following results were found.

- 77% reduction in CO2 emissions when compared to conventional manufacturing methods

- 95% reduction in water consumption when compared to conventional manufacturing methods

- 85% reduction in processes that cause toxic substance emission when compared to conventional manufacturing methods

With regards to CO2 emissions in particular, if all circuit board in global were to adopt Elephantech’s Pure Additive™ production, it would have the potential to reduce CO2 emissions by 268 billion kg-CO2,equivalent to the reduction of nine 1000 MW-class thermal power plants. 1

This LCA evaluation is based on the data and calculation logic from Carbon Footprint Analysis of Printed Circuit Board[1] by Winco K. C. Yung et al. of The Hong Kong Polytechnic University. The effect of the reduction is estimated by comparing the carbon footprint of the materials and energies required for manufacturing between the conventional manufacturing method and Pure Additive™ production. 2

This comparison is based on assumptions at the time of publishing, and while there is an expectation for emissions to be further reduced and improved by technological advancement for both conventional methods and Pure Additive™ production, there is reason to believe that the latter will maintain its superiority due to it requiring significantly fewer materials and processes.

Under the company’s mission of making the world sustainable with new manufacturing technologies, Elephantech will continue to strive to reduce CO2 emissions, water consumption, and toxic substance emissions.

1: Calculation of avoided emissions when replacing existing manufacturing methods with Elephantech’s Pure Additive™ production for the global circuit board market, including rigid, flexible and build-up circuit boards (packaged circuit boards are excluded). For the thermal power plant, calculations were made based on 1000 MW output, LNG combined-cycle power plant running at 70% capacity with an emission factor of 0.474kgCO2/kWh and an annual emission of 2.9 billion kgCO2.

2: The absolute values differ from the carbon footprint in the original study as Elephantech has unified comparison conditions such as electric power emission factor according to the company’s standards.

[1] Winco K.C. Yung, Subramanian Senthilkannan Muthu, Karpagam Subramanian, Chapter 13 – Carbon Footprint Analysis of Printed Circuit Board, Editor(s): Subramanian Senthilkannan Muthu, Environmental Carbon Footprints, Butterworth-Heinemann, 2018, Pages 365-431, ISBN 9780128128497, https://doi.org/10.1016/B978-0-12-812849-7.00013-1.

Company Overview

| Name | Elephantech Inc. |

| Establishment | January 2014 |

| Headquarters | 4-3-8 Hatchobori, Chuo-ku, Tokyo 104-0032, Japan |

| Representative | Shinya Shimizu, CEO |

| Business Description | Development of printed electronics manufacturing technology and provision of related services |

Elephantech Inc. Public Relations

pr@elephantech.co.jp